Products

Concrete batching and mixing systems

Aggregate batching system adopts four-bin one-type modular structure, the aggregate bin body is conical structure, each hopper is equipped with two discharge gates at the bottom, and the opening of the gates is controlled by pneumatic cylinders.

Key words:

Category:

Key words:

Concrete batching and mixing systems

Details

Brief description of equipment features

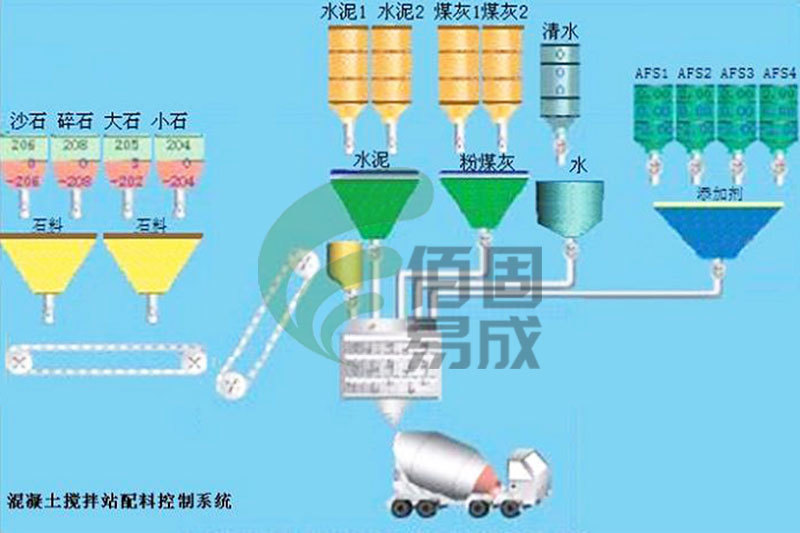

Brief description of equipment featuresAggregate batching system (batching machine)

Aggregate batching system adopts four-bin one-type modular structure, the aggregate bin body is conical structure, each hopper is equipped with two discharging gates at the bottom, and the opening of the gates is controlled by pneumatic cylinders. Each aggregate bin is equipped with a vibration device to ensure clean and smooth discharging. Aggregate metering method is separate metering, using coarse and fine weighing function.

The batching station adopts modular structure, separate measurement, and sand moisture content measuring instrument can be provided according to user's requirements;

Adopting coarse and fine weighing gate to discharging materials, with short weighing time and high precision;

Each aggregate bin is equipped with vibration device to ensure smooth discharging. The structure of the whole aggregate silo takes into full consideration of the requirements of convenient feeding and smooth discharging.

Second, belt conveying system

The inclined belt conveyor with a small inclination angle of 18 degrees is composed of driving pulley, redirecting pulley, head frame, tail frame, middle truss, outrigger, groove roller, flat roller, belt, climbing ladder and dust cover. The inclined belt conveyor and the flat belt conveyor of the aggregate batching system are equipped with two-way pull rope switches. When an emergency occurs in the working condition, the equipment stops working by pulling the pull rope switch.

The sweeper scraper plate has good sweeping effect and long service life;

The frame is designed as a standard section, which is convenient for production, transportation and installation;

The whole belt conveyor is sealed by cover, which can effectively reduce the environmental pollution, and is equipped with maintenance aisle and safety handrail, which is convenient for daily maintenance work;

The end of the inclined belt is equipped with adjustable baffle plate which can effectively adjust the falling point of aggregate and prevent the belt from deviation.

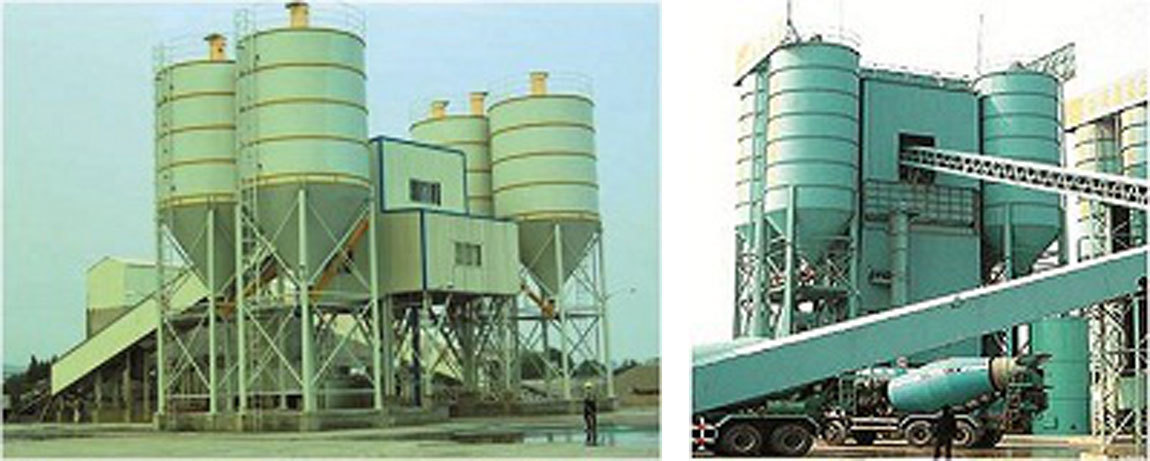

Powder storage and conveying system

According to the customer's demand, provide the best powder storage and conveying configuration. Powder silos are 50T, 100T and 200T, which are equipped with material level meter, pneumatic arch-breaking device, electric or pulse dust collector and pressure safety valve. Screw conveyor: Φ219mm, Φ273mm, Φ323mm, according to the actual capacity requirements of the classification configuration.

Powder, water and additive metering system

All of them are measured individually, and the large-capacity metering hopper is designed to meet the production of concrete of different grades. Sensors, butterfly valves, pneumatic ball valves are all brand-name products to ensure accurate measurement.

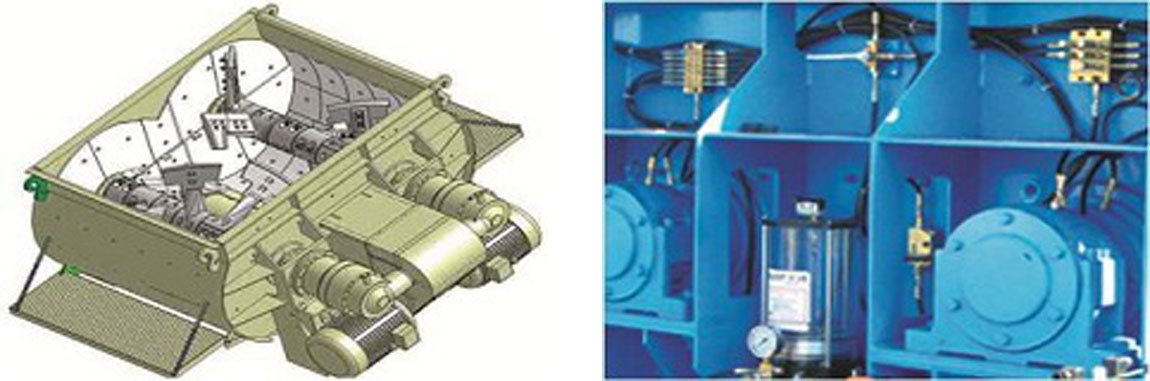

V. Mixing system

The mixing mainframe combines the advanced technology at home and abroad, and is developed and designed according to the research results of fluid dynamics and friction, with high efficiency and reliable performance. Meanwhile, it can be equipped with SICOMA, SANI and other famous domestic brands according to customers' requirements.

Multi-churn design, unique anti-shun spiral and strong space vortex movement mixer mechanism design, so that the concrete homogeneity to achieve the best results;

The material of liner and blade is high chromium wear-resistant cast iron, and the finite element analysis of its inclination is carried out for good mixing effect, fast speed and long service life;

Separation of vehicle end support and shaft end sealing, shaft end sealing adopts multiple sealing protection such as multi-point oil injection pressure sealing, labyrinth sealing, seal ring sealing and floating sealing, which makes the shaft end sealing more reliable;

Heavy-duty design, vibration damping, smooth.

Centralized lubrication system adopts 380V powerful motor, which can quickly inject lubricant into the shaft head.

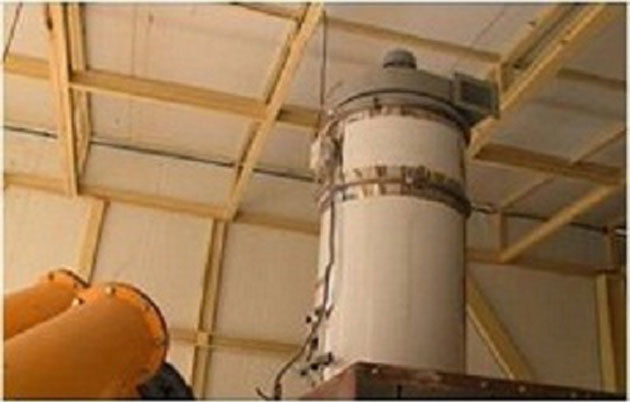

VI. Dedusting system

The main building is equipped with a dust collector, which is a bag-type dust collector and consists of vibration motor, axial fan, cylinder, top cover and box. The cloth bag dust collector makes full use of the stretchability and sealing of the cloth bag, which is made of canvas, with simple structure and low cost, and can effectively avoid the leakage of dust.

VII. Control System

Intelligent control system can automatically control the whole production process of concrete and realize the production data management of concrete.

Windows as the control platform for multi-task, multi-window, multi-user control and management system;

The monitoring combination of “industrial touch screen + microcomputer control system” puts the reliability of production control in the first place. The upper computer monitoring system carries out real-time synchronized monitoring of the data and information of the whole production process of the mixing plant;

Various parameters, status and data information of the system are in synchronous transmission status, and the production simulation screen is synchronously and dynamically displayed;

When the host fails to control the normal production of the mixing plant, the industrial touch screen can still be used for production control, thus guaranteeing the normal operation of the production and realizing the dual control of one machine;

Equipped with high-definition camera monitor, it can monitor the working condition of the whole mixing plant in the control room.

VIII. Main Building

Most of the steel structure of the main building adopts high-quality H-beam steel, with high structural strength, strong stability, and convenient installation and dismantling. The main building is sealed, dustproof, heat preservation, noise prevention, the overall appearance is beautiful and generous, the building maintenance, repair channels, space is sufficient, all maintenance channels are equipped with protective railings.

Product Parameters

Product Parametersmodel number | HZS50 | HZS60 | HZS75 | HZS90 | HZS120 | HZS150 | HZS180 | |

Theoretical productivity m3/h | 50 | 60 | 75 | 90 | 120 | 150 | 180 | |

Main machine discharge capacity L | 1000 | 1000 | 1500 | 1500 | 2000 | 3000 | 3000 | |

Discharge height m | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | 4 | 4 | |

Aggregate bin capacity (m3x number) | 7X4 | 7X4 | 15X4 | 15X4 | 15X4 | 20X4 | 25X4 | |

Aggregate scales | Measuring range kg | 0-3000 | 0-3000 | 0-4500 | 0-4500 | 0-6000 | 0-9000 | 0-9000 |

Measurement accuracy | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% | |

Powder scale | Measuring range kg | 0-700 | 0-700 | 0-1000 | 0-1000 | 0-1200 | 0-1500 | 0-1600 |

Measurement accuracy | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | |

water balance | Measuring range kg | 0-400 | 0-400 | 0-600 | 0-600 | 0-800 | 0-1200 | 0-1200 |

Measurement accuracy | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | |

Additive scales | Measuring range kg | 0-25 | 0-25 | 0-40 | 0-40 | 0-50 | 0-75 | 0-75 |

Measurement accuracy | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | |

Total power KW | 108 | 142 | 188 | 191 | 225 | 293 | 293 | |

Related Products

Online message