Products

Chemical dosage systems

This system can be used in paint, ink, food, beverage, chemical, pharmaceutical and other industrial metering control automated production with a variety of liquid raw materials according to the formula for the proportion of weighing.

Key words:

Category:

Key words:

Chemical dosage systems

Details

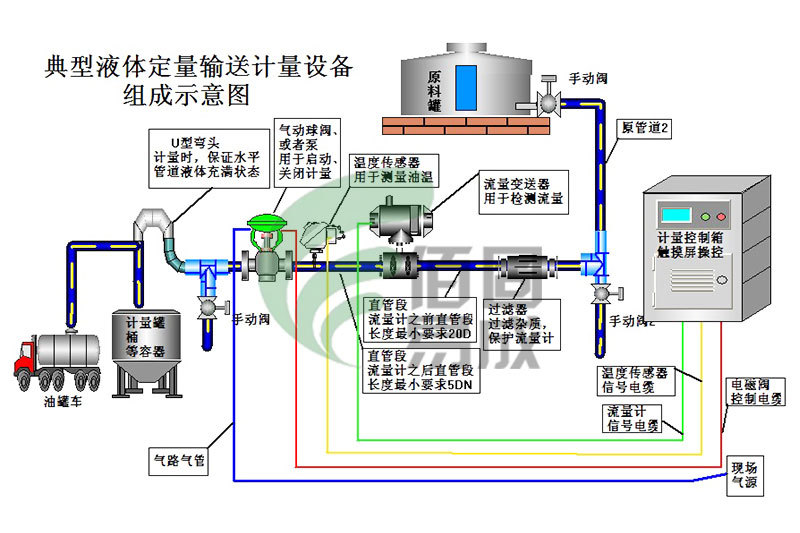

System Introduction

System Introduction This system can be used in paint, ink, food, beverage, chemical, pharmaceutical and other industrial metering control automation production that requires a variety of liquid raw materials according to the formula for the proportion of weighing. Tight control logic and procedures, can improve labor productivity, reduce human error and measurement error.

The system consists of four parts: electronic weighing and control device, weighing control instrument, PLC, and industrial computer.

Electronic weighing and control device generally refers to contain sensors, weighing barrels (tanks), feeding equipment (valves / pipeline pumps / special fluid pumps, etc.).

Generally 1 weighing control instrument connected to 1 electronic weighing and control device, 1 electronic weighing and control device can correspond to 1 or more raw materials barrels (tanks) (generally 1-18);

PLC as the logic control core performs the weighing operation of the electronic scale according to the process recipe;

Industrial computer (fully compatible with ordinary computers, more adapted to the harsh industrial environment) as the upper computer is the operation terminal of the dialogue between man and machine, the main function is to monitor the operation of the entire system based on electronic scales, the PLC to give operational orders and calibration to modify the parameters.

System Features

System Features The industrial computer is compatible with any PC-Base industrial or commercial computer, laptop;

The structure of upper computer + PLC improves the reliability of the system. The upper computer is not involved in the real-time control process of the PLC except for giving initial process parameters and control instructions. Even if the upper computer is offline, the PLC can complete the current production tasks smoothly;

Mixed programming of high-level language and assembly under Windows operating system not only ensures the reliability of the system, but also facilitates software upgrading;

Chinese (simplified or traditional) or English (on request) friendly human-machine interface, very easy to operate.

Dynamic process flow display screen, the operator can monitor the whole dosage control process intuitively through the color monitor, including the working status of the silo conveying equipment, weighing data, mixer and the working status of various process gates and valves;

Parameter modification and function setting are more flexible, and the system is highly intelligent;

Output data can be stored in the hard disk;

Leaving a port for connecting to the network;

The system can detect, monitor, display, store and print the instantaneous signals, variables and parameters in real time.

It has the function of rapid removal of zero point/tare weight.

The system can be set up to prevent misoperation and other functions;

Self-diagnostic function;

Measurement control error ± 0.25-0.5%, measurement accuracy is related to the cost and site conditions.

Key elements of the metrology software system

Key elements of the metrology software system 1. measurement control with manual, semi-automatic and fully automatic mode of operation, and can be switched at any time;

2. recipe table: recipe number, recipe name, raw material barrel number, raw material name, measurement weight, can store more than 200 kinds of recipes;

3. raw material table: raw material barrel number, raw material name, measurement level, drop, large and small material supply, valve (or pump, etc.) switching time;

4. dynamic metering program table: containing the name of the measurement of institutions, measurement time, stabilization time, yield, zero;

5. measurement of the main interface display: containing the name of the measurement organization, measurement of the total set weight, the current measurement of the actual total weight (dynamic display), the current measurement of the name of the material, the current measurement of the material set weight, the current measurement of the actual weight of the material (dynamic display);

6. measurement control interface: set the following buttons switch - measurement start, measurement stop, forced single-step stop (skip a raw material measurement), forced all stop (directly to the end of the final jump), measurement (dosage) to reset (return);

7. Statistical report on raw materials: it can count the consumption weight of a certain kind of raw material, several kinds of raw materials or all of raw materials on the same day, in the same month or in a certain period of time;

8. formula production statistics report: statistics on the day, month or a certain period of time within a certain formula, a certain number or all the production weight, 1 #, 2 # two measurement institutions can be separated or combined statistics;

9. measuring the upper and lower limits of the over-difference alarm, to facilitate the manual make-up difference;

10. hierarchical management of user operating privileges: a. Super User - can be set to adjust all the functions; b. Formula Administrator - can only set the formula; c. System Maintenance Administrator: can only be set to modify the load cell and other measurement parameters, can not see any formula information;

Related Products

Online message