Products

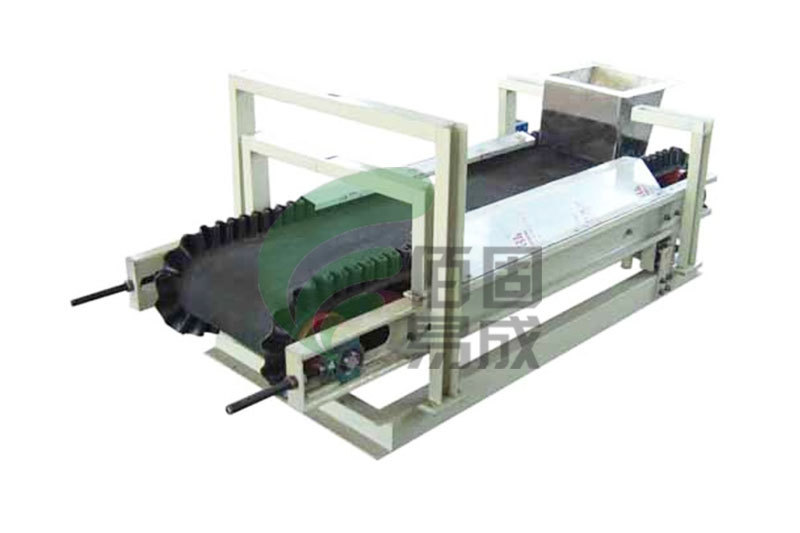

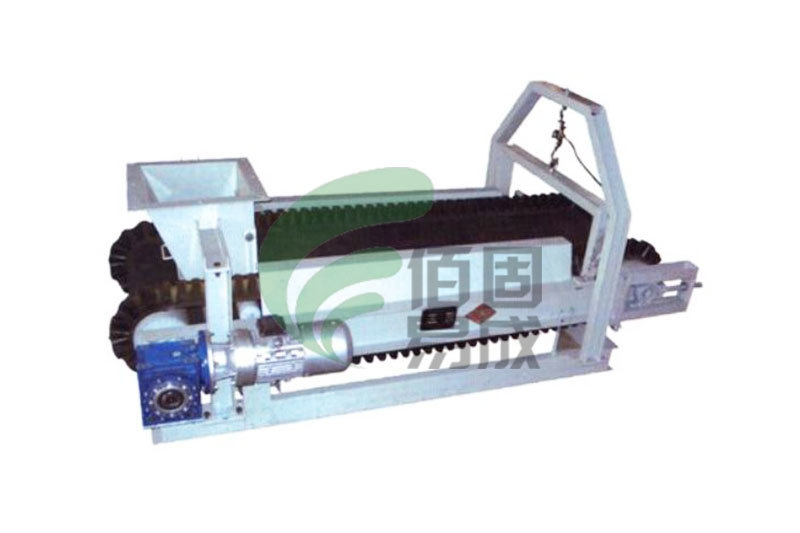

TPHanging dosing machine

TP series hanging speed regulating quantitative feeder is a new type of quantitative feeding equipment designed according to the characteristics of the supporting equipment and process requirements, which comprehensively improves the characteristics of the original quantitative feeder in various forms, inherits the advantages of the performance, improves the shortcomings, and solves the residual problem of feeding, which is a kind of advanced equipment adapted to the current technological situation.

Key words:

Key words:

TPHanging dosing machine

Details

Product Overview

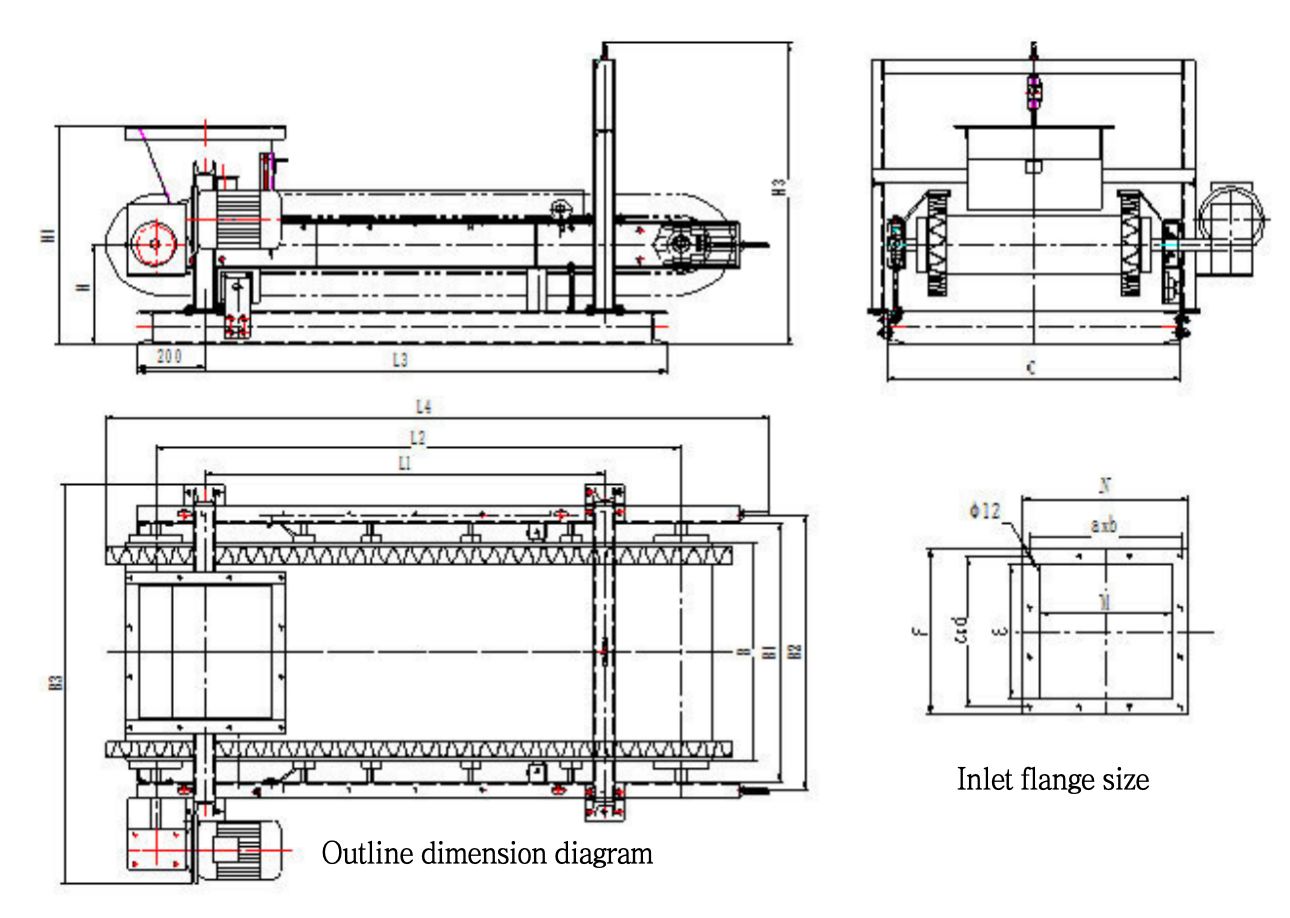

Product Overview TP series hanging speed regulating quantitative feeder is a new type of quantitative feeding equipment designed according to the characteristics of the supporting equipment and process requirements, which comprehensively improves the original quantitative feeder in various forms of characteristics, inherited the advantages of performance, improve the shortcomings, and solve the problem of feeding the legacy of the current state of the art is an advanced equipment to adapt to the current process conditions. This equipment integrates feeding and conveying, weighing and measuring and quantitative control, frequency control, dynamic feeding and measuring, advanced technology, high degree of automation, stable and reliable operation, high measuring accuracy, durability, cost-effective and so on, applicable to stand-alone and DCS centralized control system, it is the ideal equipment for automatic control of the batching system.TP series of hanging quantitative feeder is the most advanced equipment that we have developed based on the synthesis of various kinds of quantitative feeder. TP series hanging type quantitative feeder is a new type of hanging belt scale which is designed and produced by our company on the basis of various quantitative feeders and according to the characteristics of supporting equipment and process requirements. It synthesizes the advantages of the original quantitative feeder, improve and solve the remaining problems. The scale has been used by many users to prove that its technical performance is better than other belt scales. The scale has high metering accuracy, reliable operation, small maintenance cost, simple operation, not strict requirements on environmental conditions, low installation space, and solves the problems of low metering accuracy, serious zero drift, and the need for frequent periodic calibration of various types of belt scales. Our company is now widely used in building materials, chemical industry, mining, metallurgy, electric power, grain, feed, glass, ceramics, ports and other industries.

Applicable materials: powder, granule, bulk, block (≤ 30mm), moisture content to the limit of non-stick belt, the temperature is lower than 120 ℃ material metering; special belt can be transported to measure the different acidity and alkalinity of the high temperature of less than 260 ℃ material.

Features:

1, supporting direct-connected BWY series cycloid gear motor, low noise, low vibration, anti-dust, long life, high reliability;

2、The scale frame is made of cold-formed C-type steel plate, with novel structure and high strength, suitable for the design of various specifications of non-standard scales;

3、Unique hanging weighing method, high metering precision, simple structure, excellent performance, reliable and stable operation;

4、Ring shaped belt without joints, can be selected according to the process: flat belt, baffle structure, skirt belt structure;

5, hanging belt scale by three high-precision tensile sensors hanging vertically as a measuring mechanism, feeding can be used electric vibration machine, feeding belt machine, spiral or other supporting equipment.

Material types: powder, granules and small pieces of material, with a special conveyor belt can be transported to measure different acidity and alkalinity and high temperature materials.

Application: Widely used in building materials, metallurgy, electric power, chemical industry, glass, ceramics, refractory materials, mining, feed, grain, harbor and other industries.

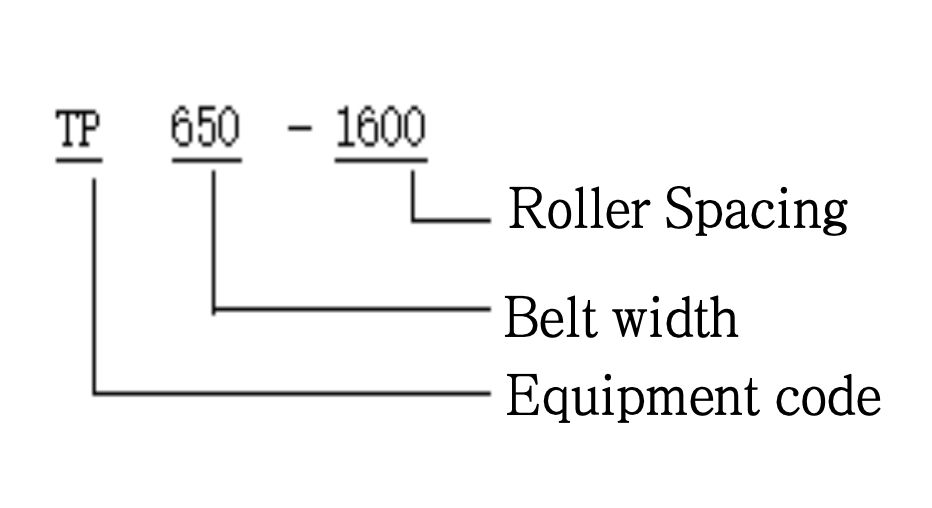

Specification

Specification

Performance & Parameters

Performance & Parameters Large adjustable range of feeding capacity: 1:10;

Measuring accuracy: better than ±0.5%;

Skirt ring belt: effectively prevent materials from scattering;

Working mode: frequency conversion speed regulation, continuous automatic feeding;

A variety of standard signal communication, a variety of control methods;

Can be easily connected with DCS control system.

With manual, automatic operation, debugging, maintenance is simple and convenient;

Lever type scale, completely eliminating the measurement error caused by the change of belt tightening force.

High metering precision; automatic detection and automatic zeroing and tare to ensure accurate metering precision.

C-type structural frame, solid structure, high strength, beautiful appearance, easy to install;

Roller center distance: 1600, 1800, 2000, 2700, 3500mm etc.;.

Belt width: 400, 500, 650, 800, 1000, 1200, 1400mm, etc.;.

Power supply: mainframe 380VAC±10%, microcomputer~220V±10%, 50Hz±2%.

Operating environment: temperature: -20℃~+50℃, relative humidity: ≤90%.

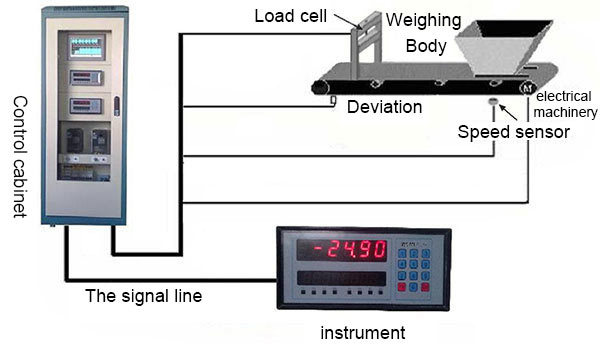

working schematic

working schematic

Selection table

Selection table

|

model number |

bandwidths(mm) |

Efficiency(kW) |

production capacity(m3/h) |

B |

B1 |

B2 |

B3 |

L1 |

L2 |

L3 |

L4 |

|

TP400 |

400 |

0.75 |

0-12 |

400 |

525 |

575 |

950 |

1200 |

1600 |

1586 |

2000 |

|

TP500 |

500 |

0.75 |

2-18 |

500 |

625 |

675 |

1050 |

1200 |

1600 |

1586 |

2000 |

|

TP650 |

650 |

1.1 |

3-24 |

650 |

775 |

825 |

1200 |

1200 |

1600 |

1586 |

2000 |

|

TP800 |

800 |

1.5 |

3-30 |

800 |

925 |

975 |

1350 |

1200 |

1600 |

1586 |

2000 |

|

TP1000 |

1000 |

2.2 |

6-60 |

1000 |

1125 |

1175 |

1560 |

1200 |

1600 |

1586 |

2080 |

|

TP1200 |

1200 |

3/4 |

8-80 |

1200 |

1325 |

1375 |

1780 |

1200 |

1600 |

1586 |

2080 |

|

TP1400 |

1400 |

3/4/5.5 |

10-100 |

1400 |

1525 |

1575 |

2000 |

1200 |

1600 |

1586 |

2080 |

|

model |

H |

H1 |

H3 |

C |

M |

N |

E |

F |

a×b |

c×d |

|

|

TP400 |

300 |

660 |

900 |

625 |

200 |

300 |

200 |

300 |

125×2 |

125×2 |

|

|

TP500 |

300 |

660 |

900 |

725 |

300 |

400 |

300 |

400 |

175×2 |

175×2 |

|

|

TP650 |

300 |

660 |

900 |

875 |

400 |

500 |

400 |

500 |

150×3 |

150×3 |

|

|

TP800 |

300 |

660 |

900 |

1025 |

500 |

600 |

500 |

600 |

137.5×4 |

137.5×4 |

|

|

TP1000 |

320 |

750 |

900 |

1225 |

700 |

800 |

500 |

600 |

162.5×4 |

137.5×4 |

|

|

TP1200 |

320 |

750 |

900 |

1425 |

700 |

800 |

500 |

600 |

162.5×4 |

137.5×4 |

|

|

TP1400 |

320 |

750 |

900 |

1625 |

700 |

800 |

500 |

600 |

162.5×4 |

137.5×4 |

|

In the case that the width of the skirt ring belt remains unchanged, the center of the drum, the production capacity is changed, and the drive power is changed accordingly.

Related Products

Online message