Products

LBQ-ILightweight chain conveyor

LBQ lightweight chain conveyor adopts low speed operation, the whole machine is stable, reliable and low failure rate.

Key words:

Key words:

LBQ-ILightweight chain conveyor

Details

Product Overview

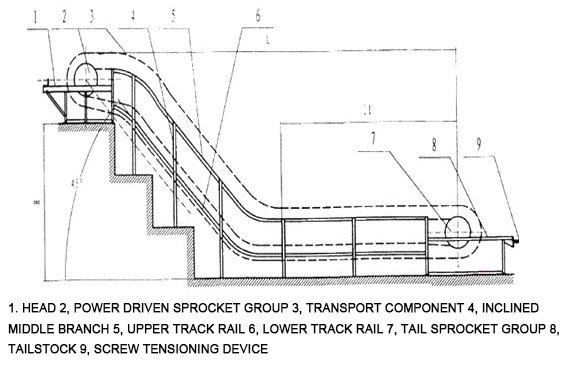

Product OverviewThe chain plate machine is composed of head frame, head guard, active sprocket group, material conveying device, middle frame, tail frame, reversing sprocket group, lower sprocket group, upper sprocket group and driving device. Chain plate machine has reasonable structural design, good performance, small running resistance, few wearing parts, safe operation, convenient maintenance, reliable operation and long service life. The chain plate machine can be installed horizontally or at an inclined angle <30°, and when installed at an inclined angle, it is equipped with a ratchet backstop mechanism. The running speed of the chain plate machine is 2.77, 3.03, 3.37, 3.64, 4.05, 4.59m/min. The optimum running speed is 2.77, 3.64m/min, and the conveying capacity is 14m3/h-56m3/h. The driving device consists of YTC gear motor, pin coupling, JZQ reducer, and driving base. There are two kinds of right and left mounting, from the rear of the machine to the conveying direction, the driving device is right mounting on the right side and left mounting on the left side. The sprocket adopts assembled structure, which consists of cast steel sprocket ring and sprocket core bolted together, with strong abrasion resistance and easy to dismantle and install. The active sprocket adopts the eye sprocket ring to prevent the chain from sliding during operation.

Technical Parameters

Technical Parameters 1、Chain pitch: standard conveyor chain

2、Plate chain width: 200-1200mm

3、Conveying speed:0.5m/min-15m/min

4、Capacity: 800kg/m

5、Metal plate chain working temperature: -20℃-100℃.

Chain plate conveyor frame is made of carbon steel or stainless steel, chain plate plate components are made of different materials.

Product Features

Product Features2、The whole machine is compact, easy to install, debug and maintain;

3、Chain plate and chain bucket have reasonable structure, good rigidity and strong impact resistance;

4、Rolling friction instead of sliding friction, low running resistance;

5、Flexible arrangement of conveying line. Compared with mesh belt conveyor, chain plate conveyor can be conveyed under the condition of larger inclination angle and smaller bending radius, so the arrangement is more flexible. The inclination angle of chain plate conveyor can be up to 30°-35°, and the bending radius is generally about 5-8m; chain plate machine is generally applicable to 0°-15° inclination angle, and the conveying inclination angle of chain bucket machine can be up to 45°;

6、When the conveying distance is ≤30m, ring chain and plate chain can be used as traction parts; when the conveying distance is >30m, in order to prevent sliding, plate chain is used as traction parts.

7、High conveying capacity, smooth and reliable operation.

8、High strength of traction chain can be used for long-distance conveying;

Forms of arrangement

Forms of arrangement

Product Classification

Product ClassificationChain conveyors are available in a variety of structural types. Chain plate conveyor can be generally categorized as follows:

1、According to the installation form of the conveyor, it can be divided into fixed type and mobile type;

2、According to the arrangement of the conveyor, it can be divided into horizontal type, horizontal-inclined type, inclined type, inclined-horizontal type, horizontal-inclined-horizontal type and so on;

3、According to the structure type of traction member, it can be divided into sleeve roller chain type, stamping chain type, casting chain type, ring chain type and detachable chain type;

4、According to the number of traction chains, it can be divided into single chain type and double chain type;

5、According to the structural type of the bottom plate, it can be divided into scale plate type (with baffle wave type, without baffle wave type, with baffle deep type, etc.) and flat plate type (with baffle flat type and without baffle flat type, etc.);

6、According to the running characteristics of the conveyor can be divided into continuous and pulsating type;

7、According to the driving method, it can be divided into electric machinery driving type and hydraulic driving type.

Product Parameters

Product Parameters|

models |

LBQ1-50 |

LBQ1-60 |

LBQ1-70 |

LBQ1-80 | LBQ1-100 | |

|

Chain bucket (plate) widthmm |

500 |

600 |

700 |

800 | 1000 | |

|

Conveying speed(m/min) |

7-14 |

|||||

|

conveying capacity |

strugglesm³/h |

15-25 |

20-35 |

30-40 |

40-50 |

50-70 |

|

|

atch sight of in a doorway (old)m³/h |

15-20 |

20-30 |

30-35 |

40-45 |

45-55 |

|

Conveying distancem |

General ≤40 Maximum 70 |

|||||

|

Maximum particle size of material to be conveyed |

coming togethermm |

80 |

100 |

140 |

160 |

200 |

|

|

catch sight of in a doorway (old)mm |

120 |

160 |

200 |

240 |

300 |

|

Allowable upward tilt angle |

coming together |

≤45º |

||||

|

|

catch sight of in a doorway (old) |

≤15º |

||||

Related Products

Online message