Products

DJLarge Inclination Belt Conveyor

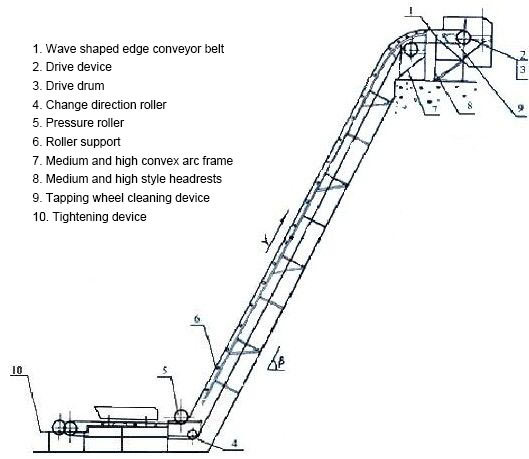

The structure of DJ type large inclination angle belt conveyor is to stick the freely retractable rubber waveform vertical “skirt” on both sides of the flat rubber transportation belt, and there is a certain strength and elasticity of the transverse partition board sticking between the skirts to form a box-shaped bucket, so that the materials can be continuously transported in the bucket.

Key words:

吨袋式包装机

Key words:

DJLarge Inclination Belt Conveyor

Details

Product Overview

Product Overview The structure of DJ type large inclination angle belt conveyor is to stick freely retractable rubber waveform vertical “skirt” on both sides of the flat rubber transportation belt, and between the skirts there is a certain strength and elasticity of the transverse partition board to form a box-shaped bucket, so that the materials are continuously transported in the bucket. It can be widely used in coal, grain, building materials, chemical industry, hydropower and metallurgy, etc. In the range of ambient temperature from -15℃ to +40℃, it can convey all kinds of bulk materials with the specific gravity of 0.5-2.5t/m³. For conveying materials with special requirements, such as high temperature, materials with acid, alkali, oil substances or organic solvents and other components, special edge conveyor belt is required, and the conveying inclination angle ranges from 0° to 90°.

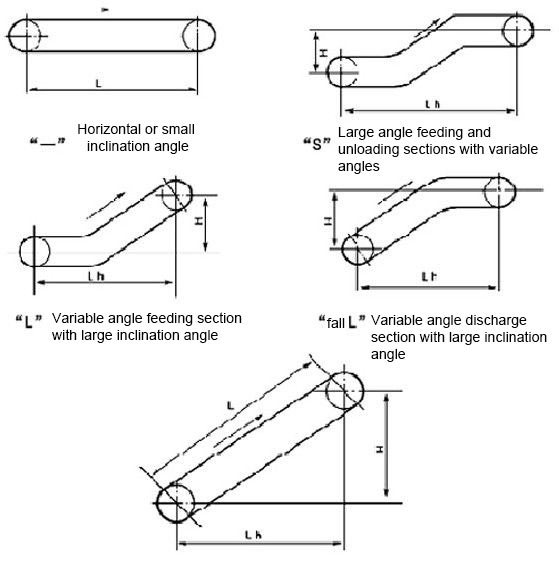

Arrangement of the whole machine:

In order to get better conditions for receiving and discharging materials, this machine adopts “Z” shape arrangement. That is to say, it has upper horizontal section, lower horizontal section and inclined section, and receives materials in the lower horizontal section and discharges materials in the upper horizontal section. The upper horizontal section and the inclined section are connected with the frame of convex arc section, while the lower horizontal section and the inclined section are connected with the frame of concave arc section in order to realize the smooth transition of the conveyor belt.

1. Upper horizontal section: In order to adapt to the requirements of different unloading heights, the head frame is divided into low head frame (head frame height H0=1000mm), middle head frame (head frame height H0=1100-1500mm) and high head frame (head frame height H0=1600-2000mm); and accordingly, the upper horizontal section is equipped with a low cambered-arc section frame and a low middle frame outriggers (equipped with a low cambered-arc section frame). Correspondingly, in the upper horizontal section, low type convex arc section rack and low type middle rack legs are used respectively (with headstock height H0=1000mm), middle type convex arc section rack and middle type intermediate rack legs (with headstock height H0=1600~2000mm), and high type convex arc section rack and high type intermediate rack legs (with headstock height H0=1600~2000mm).

2. Inclined section: No matter whether the upper horizontal section adopts low, medium or high intermediate frame legs, the inclined section adopts low intermediate frame legs. When the inclination angle of the conveyor β ≥ 45 °, it is recommended to use low intermediate frame legs.

3. Lower horizontal section: the lower horizontal section adopts low type intermediate frame legs.

Arrangement of the whole machine:

In order to get better conditions for receiving and discharging materials, this machine adopts “Z” shape arrangement. That is to say, it has upper horizontal section, lower horizontal section and inclined section, and receives materials in the lower horizontal section and discharges materials in the upper horizontal section. The upper horizontal section and the inclined section are connected with the frame of convex arc section, while the lower horizontal section and the inclined section are connected with the frame of concave arc section in order to realize the smooth transition of the conveyor belt.

1. Upper horizontal section: In order to adapt to the requirements of different unloading heights, the head frame is divided into low head frame (head frame height H0=1000mm), middle head frame (head frame height H0=1100-1500mm) and high head frame (head frame height H0=1600-2000mm); and accordingly, the upper horizontal section is equipped with a low cambered-arc section frame and a low middle frame outriggers (equipped with a low cambered-arc section frame). Correspondingly, in the upper horizontal section, low type convex arc section rack and low type middle rack legs are used respectively (with headstock height H0=1000mm), middle type convex arc section rack and middle type intermediate rack legs (with headstock height H0=1600~2000mm), and high type convex arc section rack and high type intermediate rack legs (with headstock height H0=1600~2000mm).

2. Inclined section: No matter whether the upper horizontal section adopts low, medium or high intermediate frame legs, the inclined section adopts low intermediate frame legs. When the inclination angle of the conveyor β ≥ 45 °, it is recommended to use low intermediate frame legs.

3. Lower horizontal section: the lower horizontal section adopts low type intermediate frame legs.

Technical characteristics

Technical characteristics 1. Save floor space and investment.

2. Large conveying capacity, high versatility.

3. Conveyor inclination angle: 0°-90°.

4. Convenient maintenance, rollers and other parts are the same as ordinary belt conveyor.

5. Wide range of applications: metallurgy, mining, wharf, environmental protection, grain, chemical industry, building materials and so on.

2. Large conveying capacity, high versatility.

3. Conveyor inclination angle: 0°-90°.

4. Convenient maintenance, rollers and other parts are the same as ordinary belt conveyor.

5. Wide range of applications: metallurgy, mining, wharf, environmental protection, grain, chemical industry, building materials and so on.

Structural schematic

Structural schematic

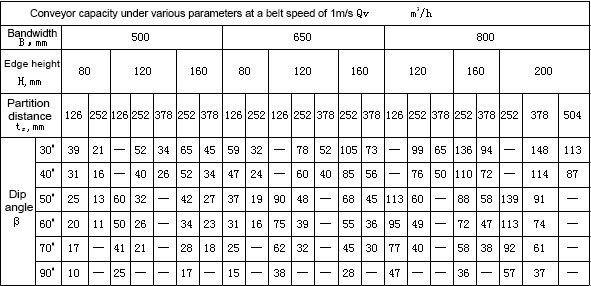

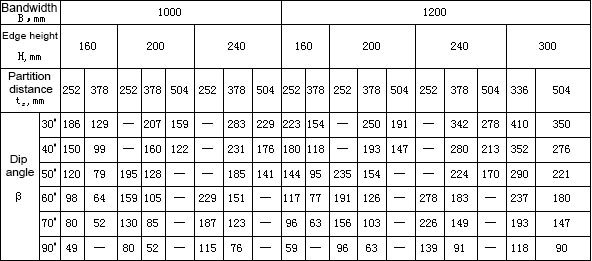

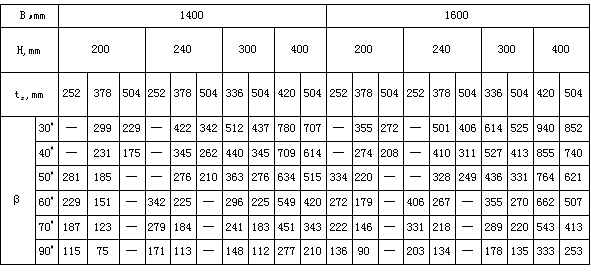

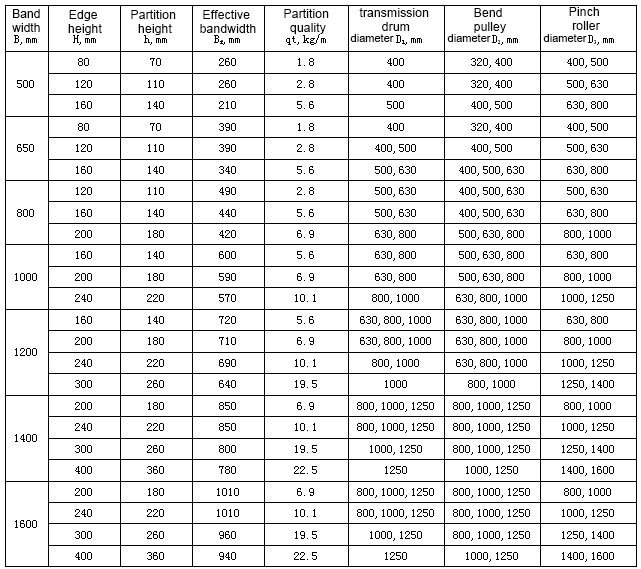

Technical Parameters

Technical Parameters

Related Products

Online message