Products

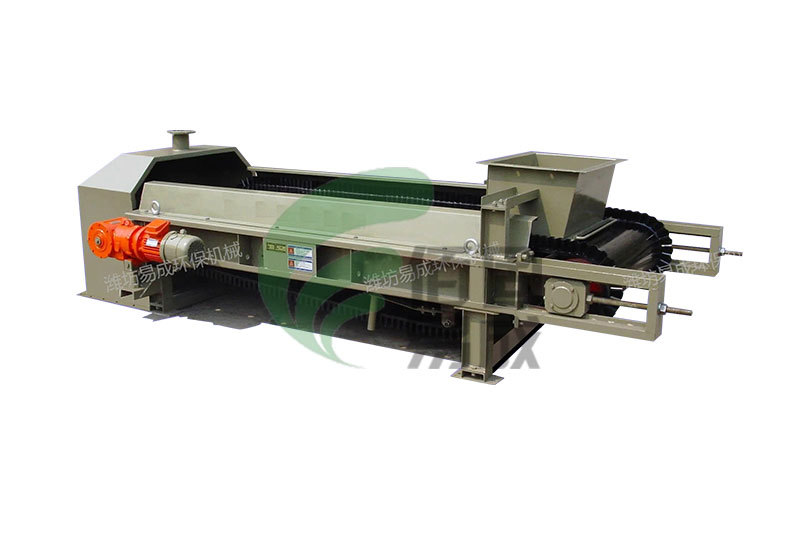

DEL/DEMSpeed regulating quantitative feeder

DEL/DEMSpeed regulating quantitative feeder, more applications in cement, mining, especially for mill batching feeding control DEL/DEM quantitative feeding belt scale-control process, for the continuous dynamic metering and quantitative feeding of bulk, lumpy, powdery materials.

Key words:

Key words:

DEL/DEMSpeed regulating quantitative feeder

Details

Product Overview

Product Overview Equipment Composition

Equipment Composition Performance Characteristics

Performance Characteristics2、The scale has automatic belt tensioning and automatic deviation correction device to keep the belt tension constant and alarm signal output for belt deviation exceeding the limit.

3, the scale body has belt inside and outside the cleaning device and discharge cover, effectively overcome the belt adhering to the material and dust.

Structural characteristics

Structural characteristics2、Ring shaped belt without joints, according to the site to choose the conveying method: flat belt, baffle structure, skirt belt structure;

3、Composed of cold-formed C-type steel plate scale frame, novel structure, high strength, suitable for various specifications of non-standard scale design;

4、Unique parallel roller weighing mechanism, more uniform force, better linearity and repeatability;

5、Reducer motor with anti-torque bracing plate, shaft-mounted structure. Directly connected with the scale body active roller, installation, commissioning and maintenance is extremely convenient.

6、Special gear speed measurement device design, with speed sensor real response motor speed, speed measurement signal is accurate and reliable.

7、Unique anti-bias belt device, imitation Shenk scale three-roller structure, can be freely adjusted tension roller.

8, quantitative feeder scale feeding device with pallet, can easily control the amount of feed and sealing material, in order to scale calibration and calibration zero.

Main technical parameters

Main technical parameters2、Feeding rate is about 50kg/h-200t/h.

3、Conveying bandwidth is 500mm-1800mm.

4、Roller center distance 1000mm-8000mm, using plug-in system, the size can be customized according to user requirements.

5、Output interface of speed regulating quantitative feeder: various optional, can be connected with DCS system.

Ambient temperature: Scale body -10℃~+60℃ Instrument -10℃~+45℃.

7. Operating power supply of speed-regulated quantitative feeder: AC220V±15% 50Hz±2% for instrument and AC380V±15% 50Hz±2% for scale.

Specification | bandwidths(mm) | Flow rate range(m³/h) | Measurement accuracy |

DEL\DEM04 | 400 | 0.5-10 | surpass0.5% |

DEL\DEM05 | 500 | 0.5-15 | surpass0.5% |

DEL\DEM06 | 650 | 1-20 | surpass0.5% |

DEL\DEM08 | 800 | 2-30 | surpass0.5% |

DEL\DEM10 | 1000 | 5-60 | surpass0.5% |

DEL\DEM12 | 1200 | 10-80 | surpass0.5% |

DEL\DEM14 | 1400 | 30-100 | surpass0.5% |

DEL\DEM16 | 1600 | 50-150 | surpass0.5% |

DEL\DEM18 | 1800 | 100-200 | surpass0.5% |

Related Products

Online message