Products

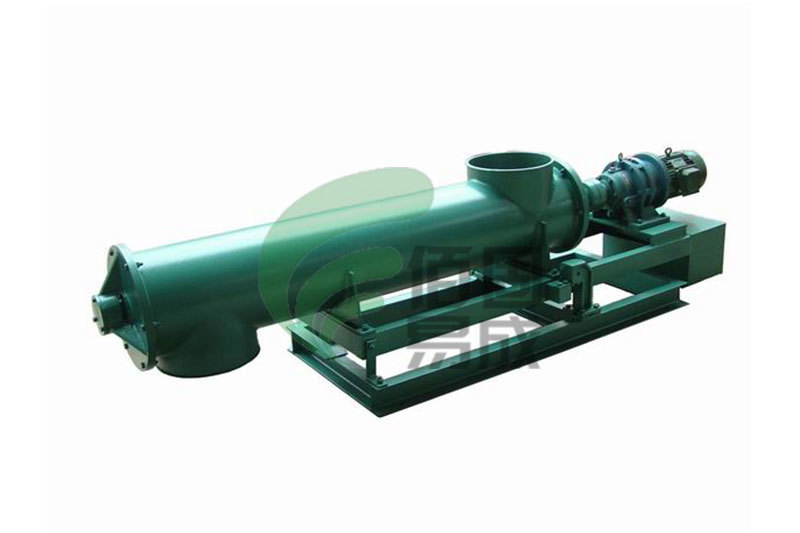

LXScrew quantitative feeder

Screw quantitative feeder is commonly known as the winch said or spiral said, is a collection of powder conveying, weighing and measuring and quantitative feeding control as a whole, electromechanical automatic control integration products;

Key words:

Key words:

LXScrew quantitative feeder

Details

Product Overview

Product Overview Performance Characteristics

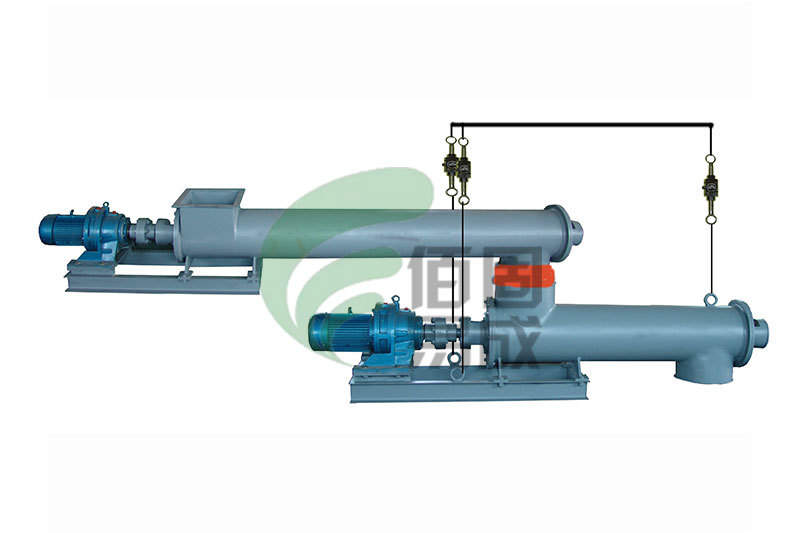

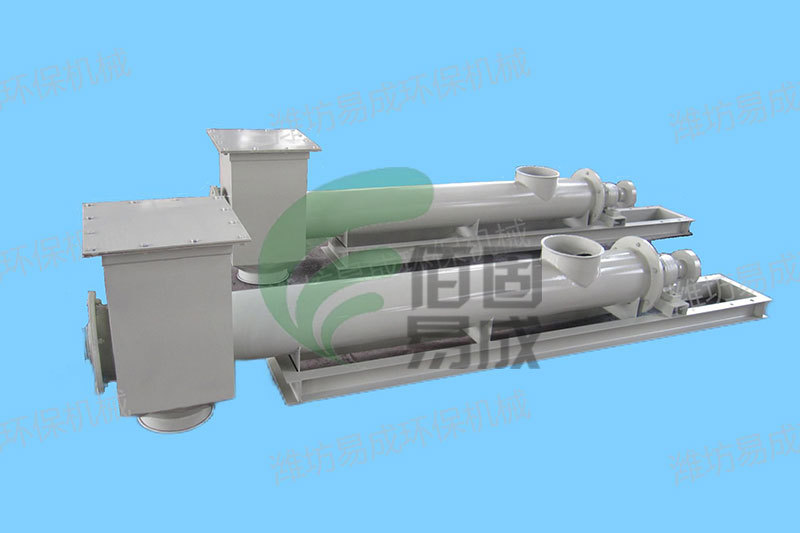

Performance Characteristics2、Flexible installation, flexible arrangement of inlet and outlet, can realize multi-point feeding and discharging, while the material also has the role of mixing and stirring, is the first choice for powder and small particles of material batching, conveying equipment.

3、More advanced technology, high precision measurement, more stable operation.

4、Feeding screw has a unique steady flow structure, in the entire cross-section of the feed port on the powder uniformly sinking, not easy to arch.

5、It can be used flexibly with other feeding equipments to realize the best automatic production process.

6、Adopting overflow feeding screw can play the functions of material locking, wind locking and flow stabilizing at the same time.

7, steady flow feeding spiral and metering spiral between the use of soft connection, not only to eliminate the steady flow feeding spiral on the metering spiral metering accuracy, but also according to the requirements of the site can be adjusted to any horizontal installation angle.

8、Measuring accuracy is better than ±1%, and the range of frequency conversion speed regulation is large.

Specification

Specification

Performance & Parameters

Performance & ParametersFrequency conversion speed range: 1:10 High conveying efficiency.

High-precision sensor, measuring accuracy is better than ±1%, stable and reliable operation.

High degree of automation of control system, can realize computer remote control management, intelligent centralized control.

Unique steady flow feeding structure, uniform feeding, no arching and no flushing; at the same time, the material is also stirring and mixing effect.

Flexible installation, the screw can be installed at any angle in the horizontal plane; flexible arrangement of feeding and discharging ports, can realize multi-point feeding and discharging.

Reasonable structure, easy installation and maintenance, long life.

The working environment temperature is usually -20~40℃, relative humidity: ≤90%.

Selection table

Selection table

|

model number |

power (output)kW |

yieldm3/h |

D |

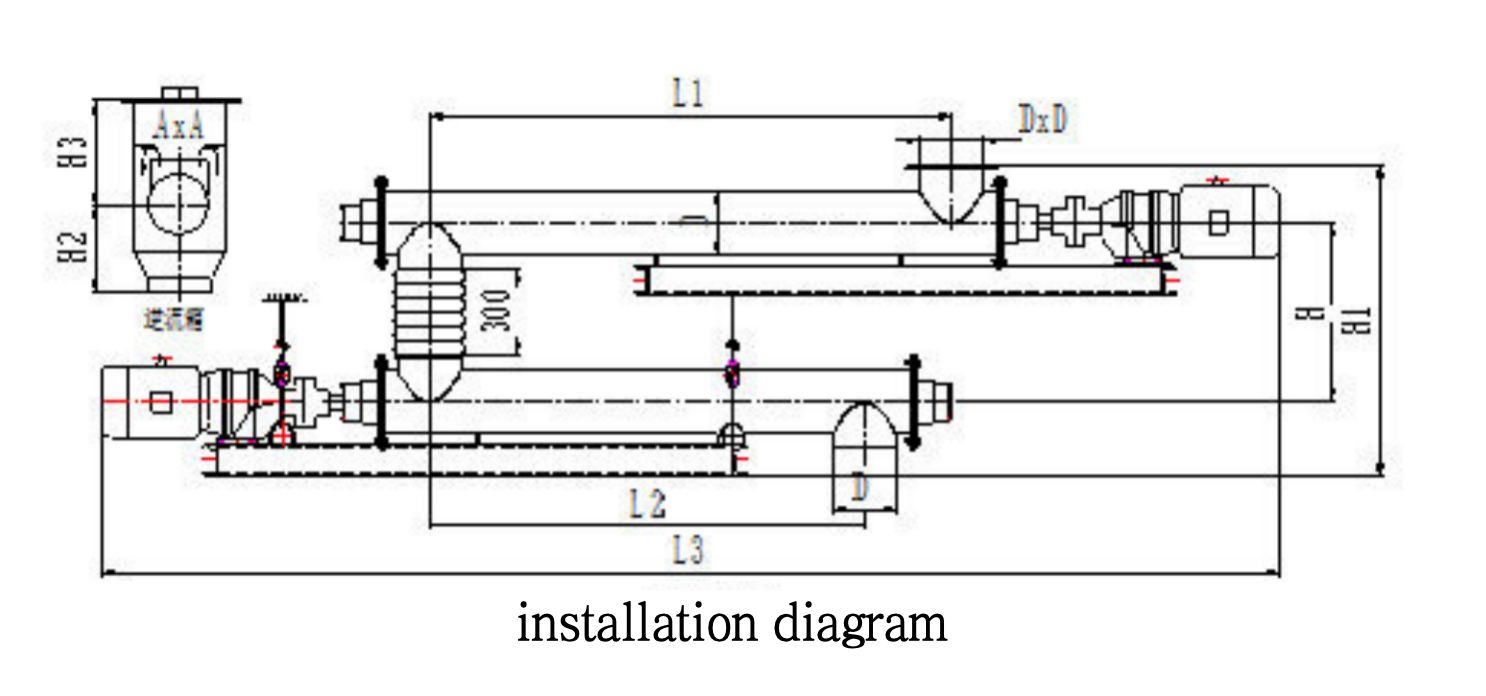

L1 |

L2 |

L3 |

H |

H1 |

H2 |

H3 |

AxA |

|

LX16 |

1.1/1.5 |

7.6 |

φ159 |

1800 |

1500 |

~3850 |

560 |

~950 |

270 |

300 |

260×260 |

|

LX20 |

1.5/2.2 |

11 |

φ219 |

1800 |

1500 |

~3920 |

620 |

~1050 |

300 |

360 |

320×320 |

|

LX25 |

2.2/3 |

22 |

φ245 |

1800 |

1500 |

~4020 |

645 |

~1100 |

315 |

400 |

350×350 |

|

LX30 |

3.0/4 |

36.5 |

φ325 |

1800 |

1500 |

~4150 |

725 |

~1250 |

380 |

480 |

450×450 |

|

LX35 |

3.0/4 |

42.5 |

φ351 |

1800 |

1500 |

~4450 |

750 |

~1300 |

400 |

500 |

480×480 |

|

LX40 |

5.5/7.5 |

66 |

φ402 |

1800 |

1500 |

~4580 |

800 |

~1400 |

420 |

520 |

520×520 |

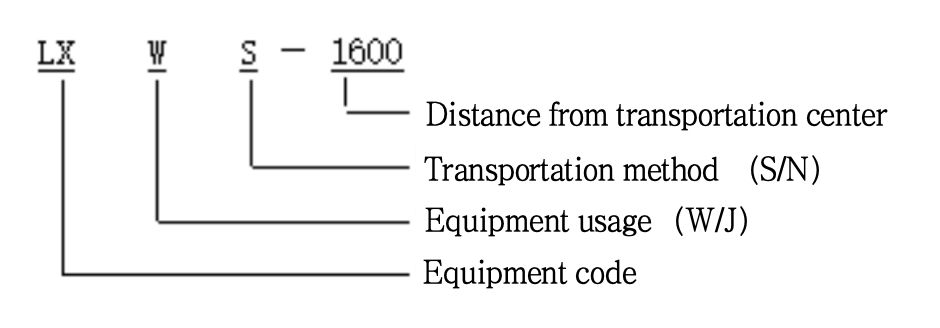

Note: 1. The dimensions in the chart and table are based on the tube spiral LX series, for example, the center of steady material is 1800, and the center of measurement is 1500.

2. The dimensions of counter-current spiral LXN series and double-tube LXS series refer to LX series.

3. The value of conveying capacity is a reference value, when the speed ratio of reducer and pitch S, and material filling coefficient are changed, the conveying capacity will be changed accordingly.

Related Products

Online message