Products

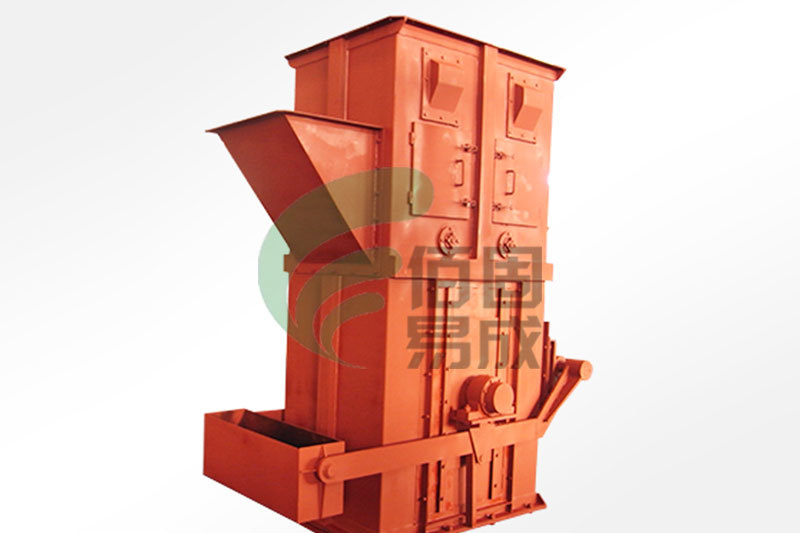

NESeries Bucket Elevator

NE Series Plate Chain Bucket Elevator is suitable for conveying powdery, granular, small lumpy abrasive or non-abrasive materials, such as raw material, cement, coal, limestone, dry clay, clinker, etc., and the temperature of the materials is controlled to be below 250℃.

Key words:

Key words:

NESeries Bucket Elevator

Details

Product Overview

Product Overview Product Features

Product Features 1、Good sealing, less environmental pollution.

2、Operation, easy maintenance, less wearing parts.

3、The use cost is extremely low due to energy saving and less maintenance.

4、Reliable operation, advanced design principle, to ensure the reliability of the whole machine operation, good sealing, less environmental pollution.

5、Good structural rigidity and high precision. The casing is folded and the middle pressure rib, and then welded, good rigidity and beautiful appearance.

6, small mechanical size, compared with the same lifting capacity of other kinds of hoist, the mechanical size of this hoist is smaller.

7, large conveying capacity, this series of elevator has a variety of specifications NE15 ~ NE800. The lifting capacity ranges from 15 to 800m3/h. Low loss, low noise and long life.

Main structure and features

Main structure and features NE series plate chain bucket elevator is composed of running parts, driving device, upper device, middle shell and lower device.

1, the upper device: installed with rails (double rows of road) to prevent the chain from swinging, backstop to prevent the hopper from rotating, the material blocked full of the lower casing, the discharge port is equipped with rubber plates to prevent the return of material.

2、Intermediate section: part of the intermediate section is equipped with rails (double rows of sections) to prevent the chain from swinging during the work, and part of the intermediate section is equipped with an access door for maintenance.

3、Lower device: Tensioning device is installed, NE15~NE50 adopts spring tensioning, and HNE100~HNE800 adopts hammer box tensioning.

4、Upper and lower sprockets adopt ZG310-570, overall tempering, HB229-269 tooth surface quenching.

5、Plate Chain: The chain plate adopts 45 # HRC36~42.

a. The plate chain has high shear strength, fatigue strength and wear-resisting performance, low failure rate and long service life;

b. Adopt lower chain speed (0.5m/s);

c. Adopting large-capacity hopper and small bucket distance, low driving power and large conveying capacity, especially suitable for lifting crushed limestone and cement clinker (≥NE50).

Working principle, characteristics and process requirements

Working principle, characteristics and process requirementsWorking Principle

NE series plate chain bucket elevator is of inflow feeding, the material flows into the hopper and is lifted to the top by the plate chain, and then discharged by itself under the effect of gravity of the material. This series of elevator specifications (NE15 ~ NE800 a total of 11 kinds) lifting capacity; and high production capacity, low energy consumption, the machine adopts the full sealing type casing chain speed is low, almost no back to the material phenomenon, so the reactive power loss is low, low noise, long life.

Features

1、It adopts inflow feeding, so that there is little extrusion and collision between each part of the conveyor as well as the materials, which makes the operation smooth and the maintenance convenient.

2、Conveyor chain adopts the face contact of plate chain, replacing the point connection of traditional bucket chain, so that the service life is improved, and the service life of conveyor chain can be more than five years.

3、Because of the inflow feeding, gravity induced discharge, bucket low line speed (15-30m/min), no back to the material phenomenon of power is only equivalent to about 40% of the ordinary ring chain bucket elevator.

4, high operating rate, trouble-free operation can reach more than 30,000 hours.

5, large conveying capacity, conveying time range 15-800m3/h.

Process requirements

Alloy steel wear-resistant sleeve roller chain:

1、Selected high quality materials produced by special steel factory, advanced heat treatment process.

1) Inner and outer chain plate: 40Cr;

2)、Pin: 20CrMnMo ;

3)、Sleeve: 20CrMo;

4)、Roller: 20CrMo; Tempered HB293-365 ;

Carbonitriding (0.5mm) quenched HRC55-62;

Carbonitriding (0.5mm) quenched HRC55-60;

Carbon nitrogen co-infiltration (0.5mm) quenching

2、German imported mesh bag type automatic turning heat treatment equipment, uniform and thorough carburizing quenching.

1)、Pin and outer chain plate are fixed, sleeve and inner chain plate are fixed to effectively reduce the wear and tear of the load bearing parts.

2)、Pin and sleeve, roller and sleeve take different clearance fits according to the material to prevent the material from abrasion and pitch elongation of the chain.

(3) The outer chain plate is stamped into a curved plate structure which is convenient for fixing the bucket and reducing the use space of the carrying mechanism.

3、Take the general inspection and broken tensile test detection means to fully guarantee the technical requirements.

Head sprocket:

1、Structure:consist of wheel hub and split gear ring.

2、Materials: hub ZG45; toothed ring 20CrMo forging steel; high strength hinge straight bolts.

3、Technical data: There are two kinds of gears: 12 teeth for low speed and 24 teeth for high speed.

4、Method of processing: wire cutting synchronous overall processing; split after installation.

5、Heat treatment method: hub tempering HB217-255; tooth ring surface quenching hardness

Tail sprocket:

1、Material: ZG35Mn.

2、Technical Data:Bright wheel without teeth fine turning.

3、Heat treatment: medium frequency quenching HRC55-60.

4、Bright teeth of the tail wheel can effectively prevent the jumping teeth and wear phenomenon caused by the head and tail not synchronized.

Technical Parameters

Technical Parametersmodel number | uplift(m³/h) | Maximum lumpiness of material | ||||

Percentage of% | ||||||

10 | 25 | 50 | 75 | 100 | ||

NE15 | 15 | 65 | 50 | 40 | 30 | 25 |

NE30 | 32 | 60 | 75 | 58 | 47 | 40 |

NE50 | 60 | 90 | 75 | 58 | 47 | 40 |

NE100 | 110 | 130 | 105 | 80 | 65 | 55 |

NE150 | 170 | 130 | 105 | 80 | 65 | 55 |

NE200 | 210 | 170 | 135 | 100 | 85 | 70 |

NE300 | 320 | 170 | 135 | 100 | 85 | 70 |

NE400 | 380 | 205 | 165 | 125 | 105 | 90 |

NE500 | 470 | 240 | 190 | 145 | 120 | 100 |

NE600 | 600 | 240 | 190 | 145 | 120 | 100 |

NE800 | 800 | 275 | 220 | 165 | 135 | 110 |

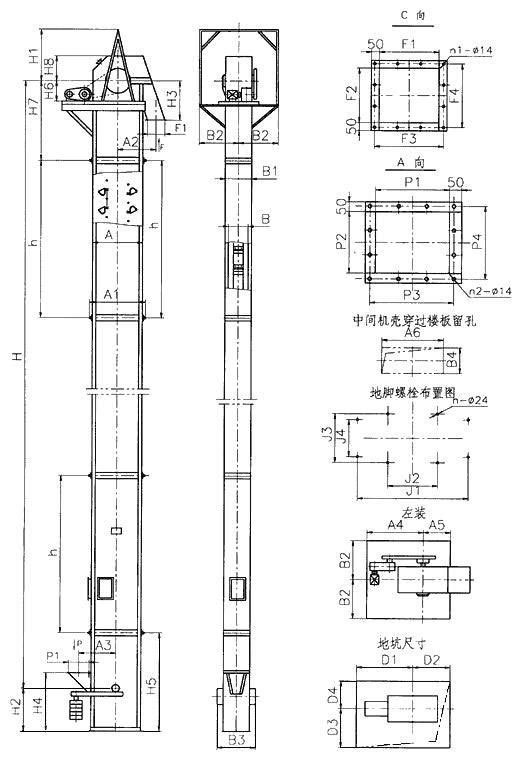

Installation Dimension Drawing

Installation Dimension Drawing

Related Products

Online message