Products

TDGBelt speed regulating quantitative feeder

TDG series speed regulating quantitative feeder is a new generation of weighing products developed by digesting, absorbing and improving on the basis of advanced technology at home and abroad; a new type of conveying, feeding, weighing and control system device.

Key words:

Key words:

TDGBelt speed regulating quantitative feeder

Details

Product Overview

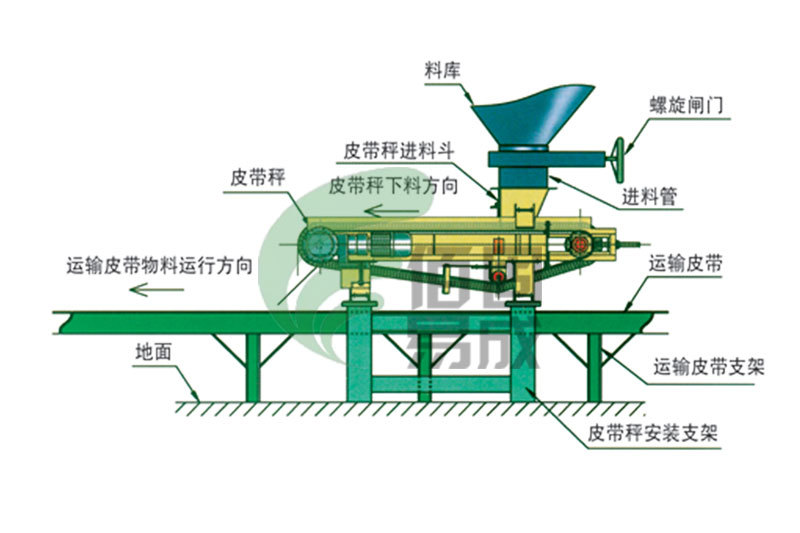

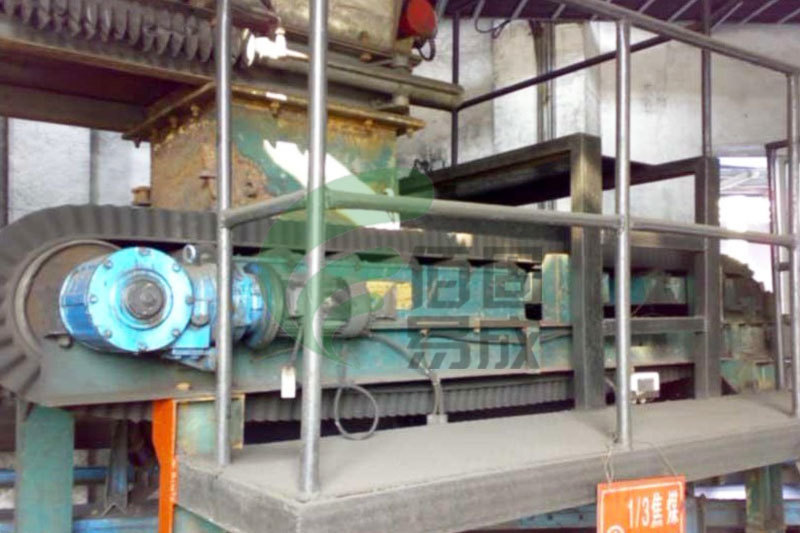

Product Overview TDG series speed regulating quantitative feeder is a new generation of weighing products developed by digesting, absorbing and improving on the basis of domestic and foreign advanced technology; a new type of conveying, feeding, weighing and control system device. It has the advantages of high weighing accuracy, stable operation and low maintenance, as well as the features of simple and convenient adjustment and various quantitative settings. It integrates conveying, controlling and measuring, and is the ideal equipment for batching, conveying and automatic continuous measuring of block, granular, solid materials or powder materials in the dynamic conveying process. It is suitable for single machine and centralized control system. The structure of the equipment is designed to be solid, rigid, beautiful in appearance, easy to install, and effective in preventing the spreading of materials. Containing automatic cleaning, automatic tightening, automatic deviation adjustment device, it is the preferred equipment for measuring and feeding materials, and also the best choice for replacing imported products.

Material types: granular, granular and small lumps of materials, with special conveyor belt can be transported to measure different acidity and alkalinity and high temperature materials.

Application scope: widely used in building materials, electric power, metallurgy, coking, chemical industry, grain, feed, mining and other industries and the more severe working environment.

Technical characteristics

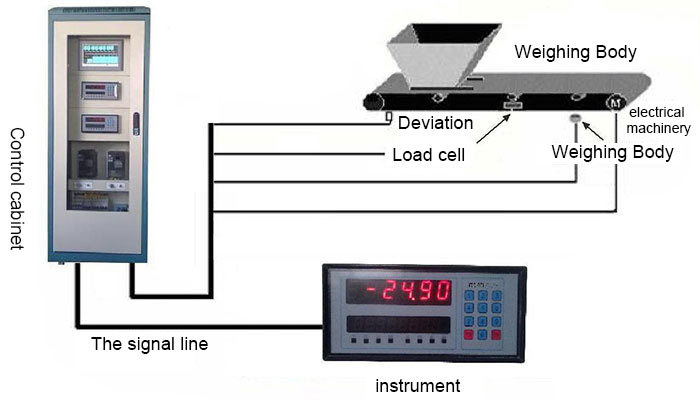

Technical characteristics Adopting our high-performance speed control belt scale can ensure the accuracy and long-term stability of measurement.

Frequency conversion speed control, stable operation, energy saving and consumption reduction, and can also meet the requirements of the site open loop or closed loop adjustment of the flow rate

Perfect alarm system enables you to find and eliminate the faults such as material blockage, material breakage, overload and belt deflection in time.

Adoption of high-temperature resistant belts, long service life in harsh environments.

High resolution load cell with minimum displacement of 0.1mm ensures accurate measurement value.

●High resolution digital pulse speed sensor ensures accurate speed value.

●Gravitational automatic tensioning device ensures constant belt tension and avoids belt slippage and excessive tension.

●Automatic belt deflection correction device avoids affecting production due to belt deflection.

●Plow shaped scraper clears the debris on the lower belt to one side to avoid damage to the belt by debris between the belt and roller surface.

●The scraper on the inside and outside of the belt avoids belt sticking and tare weight change.

●Without assistance, the belt is easy to replace, simplifying maintenance.

●The master and slave rollers adopt self-aligning bearings, which makes installation and adjustment very convenient.

●The actual feeding accuracy of various bulk materials is better than ±0.5% of the set feeding rate.

●Feeding rate is about 50kg/h-1000t/h.

●Conveying bandwidth from 500mm to 1800mm.

●Roller center distance 1000mm-8000mm, with plug-in system, the size can be customized according to user requirements.

●Output interface: various optional, can be connected with DCS system.

●Ambient temperature: Scale body -10℃~+60℃ Instrumentation -10℃~+45

● The weighing frame is made of high-strength rectangular tubes or cold-formed C-type steel plates with high rigidity and good stability.

● Shaft-mounted gear motor, low vibration and high stability.

● Belt automatic tensioning device ensures constant belt tension and measuring accuracy.

● Conveyor automatic deviation correction device to avoid affecting production due to belt deviation.

● Special structure weighing rollers, high precision bearings, small radial runout, flexible rotation and high stability.

● Thin and light belt or polyester belt, good flexural performance, light tare weight of the scale body.

● The speed measuring device is on the follower drum, the speed tracking is accurate.

● Smaller flow rate can be driven by stepping motor, accurate speed tracking and less jitter.

● The scale frame is composed of cold-formed C-type steel plate, with novel structure and high strength, suitable for the design of various specifications of non-standard scales;

Integrated direct-connected gear motor, imported technology, low noise, low vibration, anti-dust, long life, high reliability; gear motor with anti-torque support plate, shaft-mounted structure. It is directly connected with the active roller of the scale body, which is extremely convenient for installation, commissioning and maintenance.

● Circumferential non-connectorized belt, skirt belt structure;

● Uniquely designed weighing mechanism, more uniform force, better linearity and repeatability;

● Weakly magnetic gear speed measurement device design, with the speed measurement circuit real response to the motor speed, speed measurement signal is accurate and reliable;

Unique belt deflection prevention device, roller structure, freely adjustable tensioning rollers;

Scale feeding device with its own pallet, which can control the amount of feeding and sealing material, so that the scale can be calibrated and calibrated to zero;

Specification

Specification

Performance & Parameters

Performance & Parameters Measuring accuracy better than ±0.5%;.

Large adjustable range of feeding capacity: 1:10;

Working mode: frequency conversion speed regulation; continuous automatic feeding.

. Skirt ring belt: effectively prevent materials from spilling; .

A variety of standard signal communication, a variety of control methods.

Can be easily connected with DCS control system;

Pressure type metering, reduced sensor range, accurate metering, conducive to long-distance conveying.

High metering accuracy; Automatic tensioning device makes the tension constant with small error; Automatic detection zeroing and tare to ensure metering accuracy.

C-type structure frame, solid structure, high strength, beautiful appearance, easy to install.

With manual, automatic operation, debugging, maintenance is simple and convenient;

Power supply: host 380VAC±10%, microcomputer 220VAC±10%, 50Hz±2%.

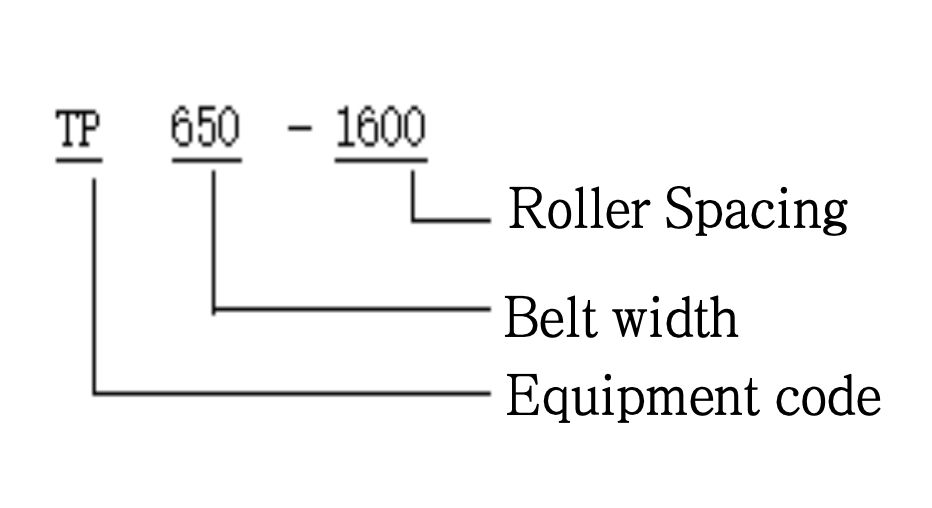

Roller center distance: 1600, 1800, 2000, 2700, 3500mm, etc;

Belt width: 400, 500, 650, 800, 1000, 1200, 1400mm, etc.;; and

Use of environment: temperature: -20 ℃ ~ +50 ℃, relative humidity: ≤ 90%;

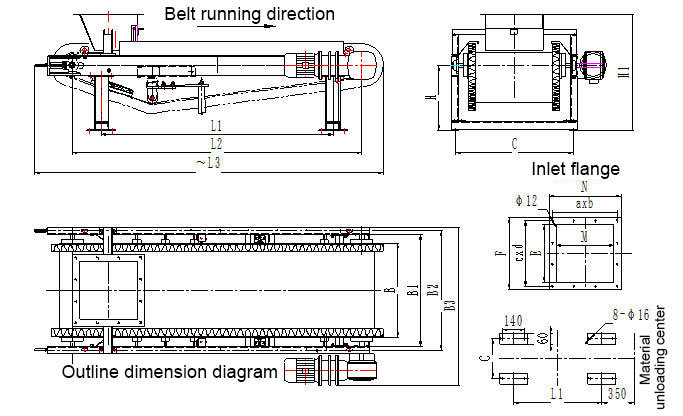

working schematic

working schematic

Selection table

Selection table

|

model number |

bandwidths(mm) |

power (output)(kW) |

yield(m3/h) |

B |

B1 |

B2 |

B3 |

L1 |

L2 |

L3 |

|

TDG400 |

400 |

0.75 |

0-12 |

400 |

525 |

575 |

840 |

1600 |

2000 |

2415 |

|

TDG500 |

500 |

0.75 |

2-18 |

500 |

625 |

675 |

940 |

1600 |

2000 |

2415 |

|

TDG650 |

650 |

1.1 |

3-24 |

650 |

775 |

825 |

1100 |

1600 |

2000 |

2415 |

|

TDG800 |

800 |

1.5 |

3-30 |

800 |

925 |

975 |

1250 |

1600 |

2000 |

2415 |

|

TDG1000 |

1000 |

2.2 |

6-60 |

1000 |

1125 |

1175 |

1460 |

1600 |

2000 |

2520 |

|

TDG1200 |

1200 |

3/4 |

8-80 |

1200 |

1325 |

1375 |

1670 |

1600 |

2000 |

2520 |

|

TDG1400 |

1400 |

3/4/5.5 |

10-100 |

1400 |

1525 |

1575 |

1880 |

1600 |

2000 |

2520 |

|

model |

H |

H1 |

C |

M |

N |

E |

F |

a×b |

c×d |

|

|

TDG400 |

450 |

810 |

565 |

200 |

300 |

200 |

300 |

125×2 |

125×2 |

|

|

TDG500 |

450 |

810 |

665 |

300 |

400 |

300 |

400 |

175×2 |

175×2 |

|

|

TDG650 |

450 |

810 |

815 |

400 |

500 |

400 |

500 |

150×3 |

150×3 |

|

|

TDG800 |

450 |

820 |

965 |

500 |

600 |

500 |

600 |

137.5×4 |

137.5×4 |

|

|

TDG1000 |

450 |

900 |

1165 |

700 |

800 |

500 |

600 |

162.5×4 |

137.5×4 |

|

|

TDG1200 |

450 |

900 |

1365 |

700 |

800 |

500 |

600 |

162.5×4 |

137.5×4 |

|

|

TDG1400 |

450 |

900 |

1565 |

700 |

800 |

500 |

600 |

162.5×4 |

137.5×4 |

|

In the case that the width of the skirt ring belt remains unchanged, the center of the drum, the production capacity is changed, and the drive power is changed accordingly.

Related Products

Online message