Products

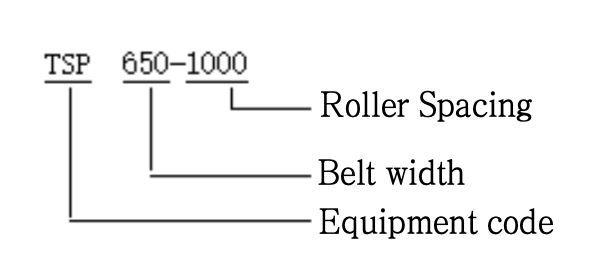

TSPDouble Belt Loss-in-Weight Quantitative Feeder

TSP series double-belt loss-in-weight quantitative feeder is our regular mature products, the suspension method and zero-point stabilization greatly improve the metering accuracy.

Key words:

Key words:

TSPDouble Belt Loss-in-Weight Quantitative Feeder

Details

Product Overview

Product Overview TSP series double-belt loss-in-weight quantitative feeder is our regular mature products, the suspension method and zero stabilization greatly improves the metering accuracy. Compared with TP and TDG series speed feeders, it has high metering precision, flexible installation, simple operation and convenient maintenance. Applicable to single machine, instrumentation, DCS centralized control system and other control systems, is the measurement and dosing of the first choice of the ideal equipment, especially suitable for dosage systems with high precision materials.

Material type: powder, granule and small lump material, with special conveyor belt can convey measuring different acidity and alkalinity and high temperature material.

Application scope: Widely used in building materials, metallurgy, electric power, chemical industry, mining, grain and other industries. Matching with feeding equipment (electromagnetic vibrating feeder, belt conveyor, screw or disc feeder), it can realize automatic measuring feeding.

Specification

Specification

Performance & Parameters

Performance & Parameters 1. Measuring accuracy: better than ± 0.125%;.

2. Two times measurement, error compensation, high measurement precision;

3. Working mode: continuous automatic feeding;

4. Skirt ring belt: effectively prevent materials from scattering;

5. C-type structure frame, solid structure, high rigidity, beautiful appearance, easy to install;

6. A variety of standard signal communication, a variety of control methods, can be conveniently connected with DCS control system;

7. Use of environment: temperature: -20 ℃ ~ +50 ℃, relative humidity: ≤ 90%;

8. Roller center distance: 2800, 3000, 3200mm, etc.; and

9. Belt width: 400, 500, 650, 800, 1000, 1200mm, etc.; and

10. Power supply: host 380VAC ± 10%, control system ~ 220V ± 10%, 50Hz ± 2%.

Working Principle

Working Principle The control system controls the upper belt to work firstly according to the set value of discharging, stabilizes the material and then measures the weight. After that, the lower belt works to continuously and stably convey the material and measure the weight again, and calculates the difference between the two measuring values at the end of the feeding and the end of the discharging to get the accurate value of the discharging this time, and then compares the discharging value with the set value, and automatically transmits its error to the next cycle for compensation. This ensures high precision output of the set amount of material.

Selection table

Selection table| model number | bandwidths(mm) | power (output)(kW) | yield(m³/h) | Overall dimensions (L×W×H) | Inlet flange size |

| TSP400 | 400 | 0.75×2 | 0-12 | 2200×950×1160 | 200×200 |

| TSP500 | 500 | 0.75×2 | 2-18 | 2200×1050×1160 | 300×300 |

| TSP650 | 650 | 1.1×2 | 3-24 | 2200×1200×1160 | 400×400 |

| TSP800 | 800 | 1.5×2 | 3-30 | 2200×1350×1160 | 500×500 |

| TSP1000 | 1000 | 2.2×2 | 6-60 | 2500×1560×1230 | 700×500 |

| TSP1200 | 1200 | 3/4×2 | 8-80 | 2500×1780×1230 | 700×500 |

Related Products

Online message