Products

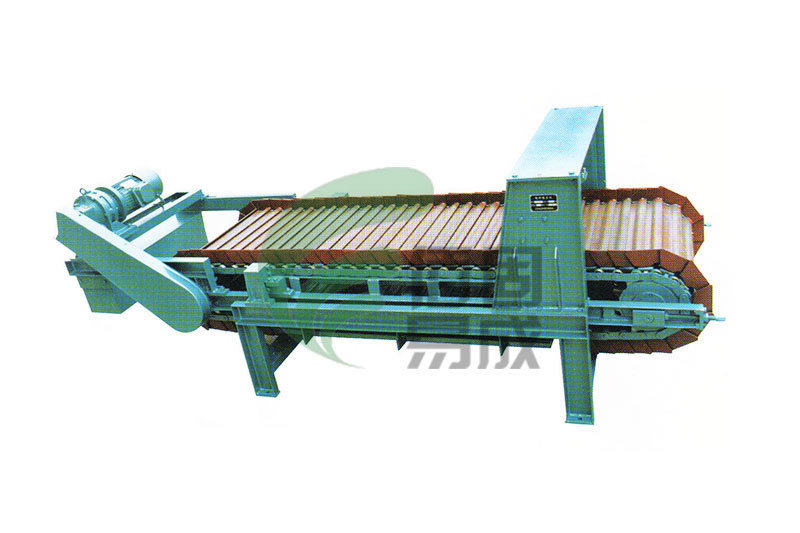

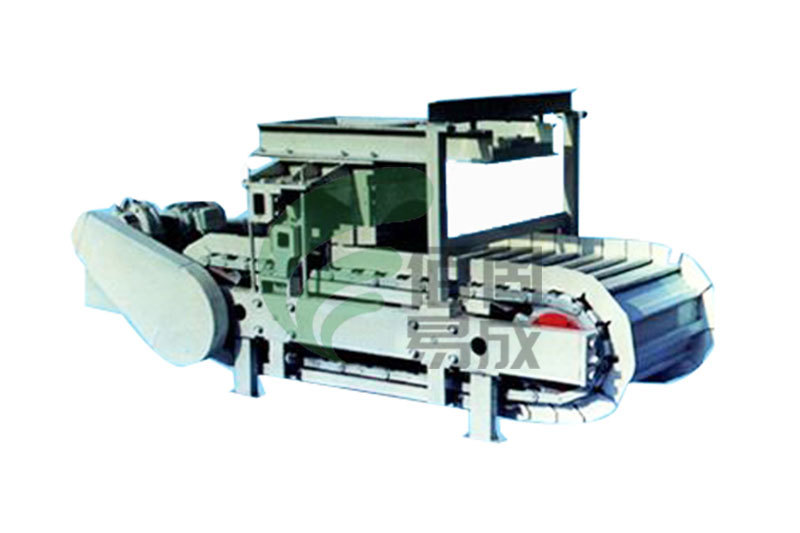

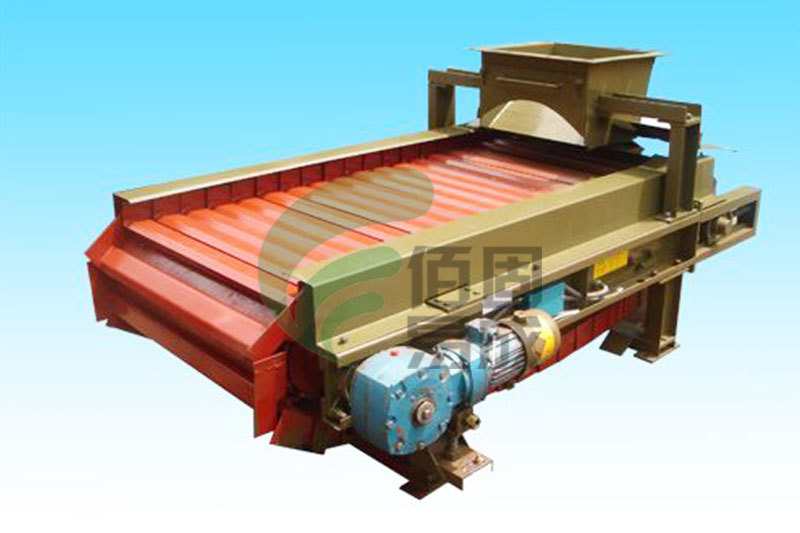

Chain plate type quantitative feeder

The new chain plate type quantitative feeder developed and produced by our company is mainly used for feeding the silo in the material conveying system in the production site, realizing the continuity of the material conveying process, improving the efficiency of the material conveying, saving energy and protecting the environment, and it is the updated product and the direction of development of the current feeder.

Key words:

Key words:

Chain plate type quantitative feeder

Details

Product Overview

Product Overview Advantages of chain feeder

Advantages of chain feeder Structure and working principle

Structure and working principle 1、Structure

Chain plate feeder consists of bin interface, guide chute, manual gate device, driving chain wheel set, carrier wheel set, bottom frame and other parts, each part is connected by bolts, handling and assembling, it can be split and whole, and it is suitable for ground or underground.

The guide chute is installed in the lower part of the silo mouth, and the driving sprocket wheel set consists of chain sprocket plate, sprocket wheel, bearing seat, electric motor and its reducer mounted on the bottom frame, with driving handwheel on the outer side. The two sides under the guide trough are equipped with sealing guards, and the manual gate device can realize the opening and closing of the outlet or the adjustment of the size of the discharged material.

The end side of the return chain wheel of the driving chain wheel is equipped with a tensioning device, which is used to tension the chain chain plate for parallel operation.

The material of the driving chain plate is 16Mn, which is friction-resistant and has a long service life.

. 2、Working Principle

When the material falls into the guide trough from the mouth of the silo to the chain plate at the same time, the driving chain wheel is started by the motor and driven by the chain wheel to drive the chain chain plate to export the material and complete the feeding process of the material, the size and efficiency of the feeding volume (speed) can be realized by the size of the gate opening and the speed control of the speed changer. The gap between the inner side of the guide groove and the chain wheel and chain plate, if there is any leakage of material, it will be blocked by the sealing plate under the inner side of both sides.

Related Products

Online message