Products

Fertilizer special dosage packaging production line

The annual output of 100,000~300,000 tons of “economic and practical microcomputer batching (BB) fertilizer production line” researched and developed by our company is the key model promoted by the Ministry of Agriculture for soil testing and formula fertilizer application, which is in a leading position in China and is widely used in the continuous production of large and medium-sized BB fertilizers (blended fertilizers) enterprises.

Key words:

Category:

Key words:

Fertilizer special dosage packaging production line

Details

Product Overview

Product OverviewThe annual output of 100,000~300,000 tons of “economic and practical microcomputer batching (BB) fertilizer production line” researched and developed by our company is the key model promoted by the Ministry of Agriculture for soil testing and formula fertilizer application, which is in a leading position in China and is widely used in the continuous production of large and medium-sized BB fertilizers (blended fertilizers) enterprises.

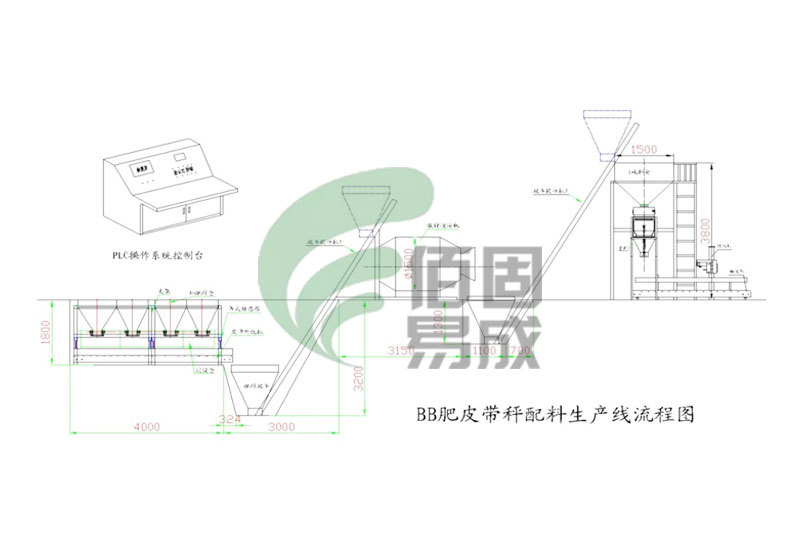

process

process Equipment Composition

Equipment Composition Equipment Characteristics

Equipment Characteristics 1、Multi-type of batching. With microcomputer dosage, high dosage precision, fast dosage speed, applicable to 3~12 kinds of materials, can match 8~40 tons per hour;

2、Economic and practical new type. Microcomputer control, tend to intelligent, automation, less investment in equipment, low operating costs.

3、Automation of batching system. Microcomputer batching system automation, automatic fall compensation, boot self-test, sound and light alarm. Quantitative and cumulative measurement, high precision measurement, easy operation, reliable operation.

4、Intelligent mixing system. Raw material lifting, mixing, unloading time can be set by yourself, the system automatically controls the running time according to the set parameters, fast operation and high production efficiency.

5、Computerized quantitative packaging system. Imported sensors and meters, high metering accuracy, batching accuracy ≤ ± 0.5%, packaging accuracy ≤ ± 0.2%, reliable operation.

6、Equipment structure is designed individually. Individually designed for the user's site, above ground type and underground type.

7、Convenient monitoring and inquiry. The equipment prints the report and inquires the accurate situation of instantaneous dosage at any time. It has the function of on-site or remote monitoring system, which is connected with a large screen displaying the current formula.

8、Long life. The equipment all adopts stainless steel plate, multi-thickness, corrosion-resistant, to ensure long life of the equipment.

9, reduce costs. Microcomputer control, simple operation, the whole set of production line 3-5 people can, saving personnel, power consumption is also greatly reduced.

Related Products

Online message