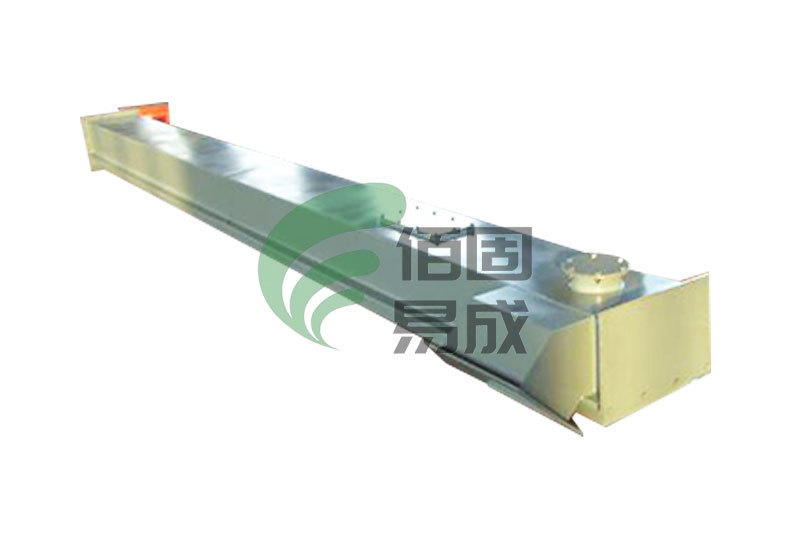

Air delivery chute

Air transport chute is suitable for conveying cement and other easily fluidized powder materials. It is not used for materials with large particle size, more water and poor fluidization performance. The tank USES a high pressure centrifugal fan (type 9-19) as the power source, so that the materials in the closed transportation chute can keep the fluidized flow to the inclined downward end slowly. The main part of the machine has no transmission parts, convenient sealing operation and management, easy to start and stop, little noise, no lubrication, almost no maintenance, light weight of equipment, large transport capacity, easy to change the direction of transport, the use of new coating permeability layer and other advantages.

Key words:

Category:

Details

| Specifications | xz200 | xZ250 | xZ315 | xZ400 | xZ500 | xZ630 | xz800 | ||||

| Width of the tub | mm | 200 | 250 | 315 | 400 | 5o0 | 630 | 800 | |||

| Transmission capacity | 4 | cement | T/h | 22 | 40 | 70 | 130 | 220 | 320 | 400 | |

| Raw meal | 16 | 30 | 55 | 100 | 165 | 245 | 310 | ||||

| 6° | cement | 40 | 65 | 120 | 250 | 400 | 610 | 765 | |||

| Raw meal | 30 | 55 | 90 | 185 | 300 | 455 | 565 | ||||

| 8° | cement | 50 | 8o | 140 | 300 | 470 | 720 | 900 | |||

| Raw meal | 35 | 65 | 110 | 225 | 355 | 540 | 670 | ||||

| 10° | cement | 60 | 100 | 170 | 380 | 570 | 900 | 1080 | |||

| Raw meal | 45 | 8o | 140 | 285 | 425 | 670 | 8o0 | ||||

| 12° | cement | 70 | 120 | 205 | 455 | 685 | 1080 | 1295 | |||

| Raw meal | 50 | 95 | 165 | 340 | 510 | 805 | 960 | ||||

| Need air pressure | KPa | 4-5.5 | |||||||||

| Air demand | m/m2.min | 1.5-2 | |||||||||

Related Products

Online Message