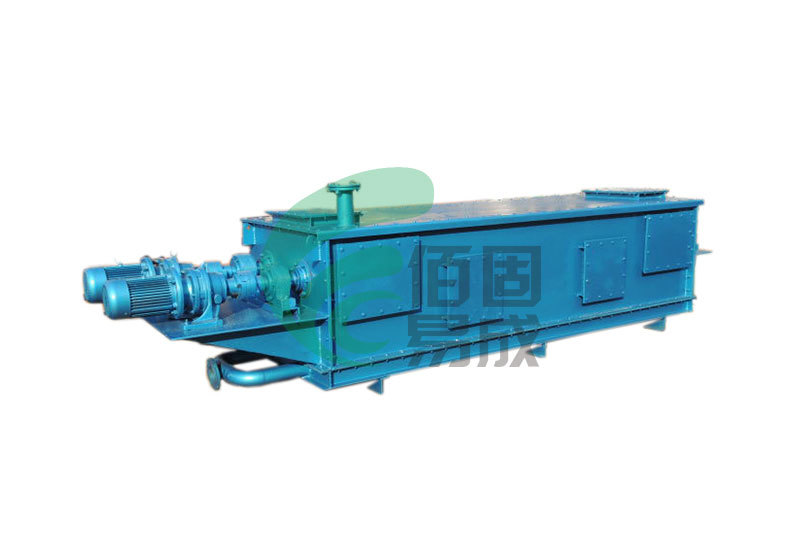

Compound machine mixer

The pneumatic and mechanical composite mixer developed by our company is developed on the basis of summarizing the advantages of mechanical and pneumatic mixers. The composite mixer not only has the characteristics of uniform mixing of mechanical mixers, but also The pneumatic mixer has the characteristics of fast mixing, low power and low consumption of parts, especially the process layout does not require a special process route, and it only needs to be installed and used with a slight improvement in the bypass of the conveying equipment. After the production and use of many cement enterprises, it is well received by users. It can also be used for mixing other powdery materials! Can be customized according to the specific requirements of customers!

Key words:

Category:

Details

2. The moisture content is less than 1.5%.

3. The specific gravity of the material is less than 2t/㎥.

4. No viscosity.

5. The feed metering is accurate.

| Model | FH500*3000 | FH630*3500 | FH800*4000 | FH500*3000-2 | FH630*3500-2 | FH800*4000-2 | FH1000*5000-2 |

| Mixing capacity m³/h | 30-100 | 50-150 | 100-300 | 50-150 | 100-300 | 300-500 | 400-800 |

| Shaft power KW | 2.2 | 3 | 5.5 | 2*2.2 | 2*3 | 2*5.5 | 2*5.5 |

| Fan power KW | 2.2 | 3 | 4 | 4 | 5.5 | 7.5 | 15 |

| Total power KW | 4.4 | 6 | 9.5 | 8.4 | 11.5 | 18.5 | 26 |

Related Products

Online Message