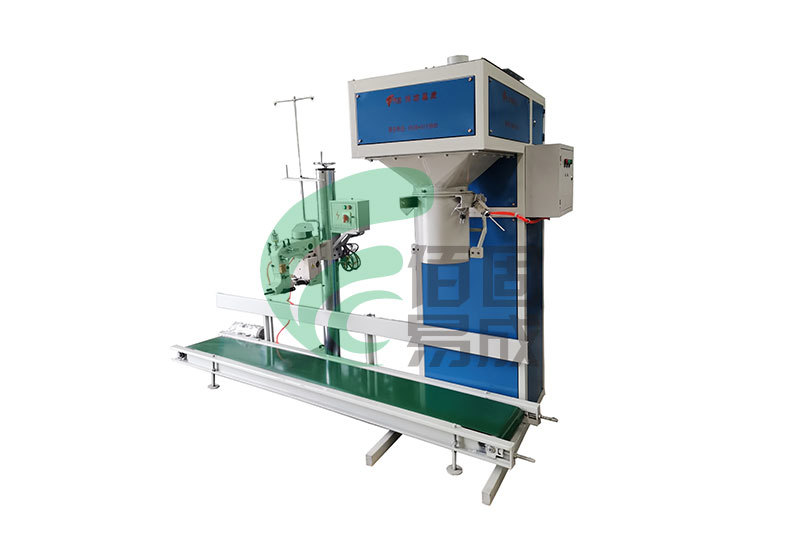

Granular Packaging Machine

The granular packing machine, also called open-mouth bagging machine, is a new generation intelligent packing machine developed by us. It is suitable for metering, packing, and bag-sewing of various granular or powdery materials that are loose and flowable such as chemical fertilizers, seeds, fodder, etc. This equipment is a fast, quantified packing unit that integrates filling, metering, sealing, packing and delivering. It mainly packs in 25-50kg bags, and it comes with two types: MDCS25 and MDCS50. It features reasonable structure, graceful shape, stable performance, unpowered packing, energy efficiency, easy operation, and precise weighing.

Key words:

Category:

Details

| The name of the | unit | Technical parameters | |||

| Product model | MDCS251 | MDCS252 | MDCS501 | MDCS502 | |

| Production capacity | t/h | 8 | 12 | 10 | 15 |

| Weighing scale | kg | 5~25 | 5~25 | 25~50 | 25~50 |

| Measuring accuracy | ±0.1%~0.5% | ||||

| Bag weight pass rate | ≥95% | ||||

| Belt power | kw | 0.37 | |||

| The belt width | mm | 350 | |||

| Sewing machine | column | ||||

| Air pressure | Mpa | 0.4-0.8 | |||

| Equipment weight | Kg | 300 | 400 | 400 | 55o |

| Installation dimensions | mm | 3000*1100*2600 | 4800*1100*2600 | 3000*1100*2600 | 4800*1100*2600 |

Related Products

Online Message