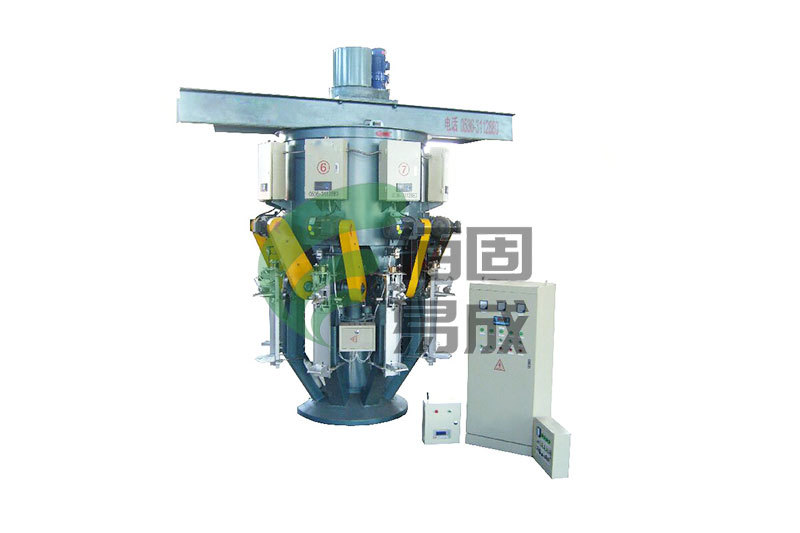

Impeller Packing Machine

The MQB50 series full automatic impeller fixed type packing machine is our new self-designed and manufactured product. Thanks to the continuous R&D of our technicians, it has been used by multiple construction material manufacturers nationwide and is widely praised by users. The whole working process of this packing machine is computer monitored; its instruments display info in real time; it diagnoses faults and recovers automatically; it automatically stops in case of bag dropping or bag breaking; it also has functions like anti-blocking and automatic shutdown; it measures twice for every filling, increasing the precision significantly. The unique electromagnet bag dropping and pneumatic door-shutting system have perfected the bag dropping function, ensuring no jamming or leaking of the nozzle. All nozzles are powered independently without air resistance and with high output. Thanks to a sealed machine body, it has improved working environment and lowered labor intensity, and is therefore well received by customers.

Key words:

Category:

Details

It is mainly used to pack cement on cement production lines. It can also be used for quantitative packing of powdery or granular materials with good flowability such as talcum powder, gypsum powder, and lime powder.

The material goes to the cellular wheel from the external material bin, and then enters the cement outlet bucket through the material inlet on the machine base, and is conveyed evenly to the outlet through the steady rotation of the impeller. Insert the packing bag, gently press the limit switch on the right side of the material nozzle, and the sealing cylinder retracts; the material nozzle is unblocked, the filling begins and the material falls into the bag steadily. With more materials enter the bag, the signals sending from the sensors to the microprocessor are constantly changing. When the required filling weight is met, the microprocessor sends out a signal, telling the sealing cylinder to extend and seals the material outlet; in the meantime, the electromagnetic pull rod moves upward, and the material bag drops, thus realizing full automatic packing requirements of automatic metering and bag dropping.

| The name of the | unit | Technical parameters | |||

| Product model | MQB50-I | MQB50-I | MQB50-Ⅲ | MQB50-IV | |

| Discharging mouth | a | 1 | 2 | 3 | 4 |

| Production capacity | t/h | 10~15 | 20~30 | 30~45 | 40~60 |

| Discharge power | kW | 4 | 4×2 | 4×3 | 4×4 |

| Weighing scale | kg | 20~50(adjustable) | |||

| Measuring accuracy | kg | ±0.3 | |||

| Bag weight pass rate | ≥95% | ||||

| Feed the flange | mm | 280×260 | 620×260 | 1350×260 | 1845×260 |

| Equipment weight | kg | 500 | 850 | 1080 | 1360 |

| Length by width by height | mm | 680×1150×1330 | 1140×1150×1330(1780) | 1760×1150×1330(1780) | 2280×1150×1330(1780) |

Related Products

Online Message