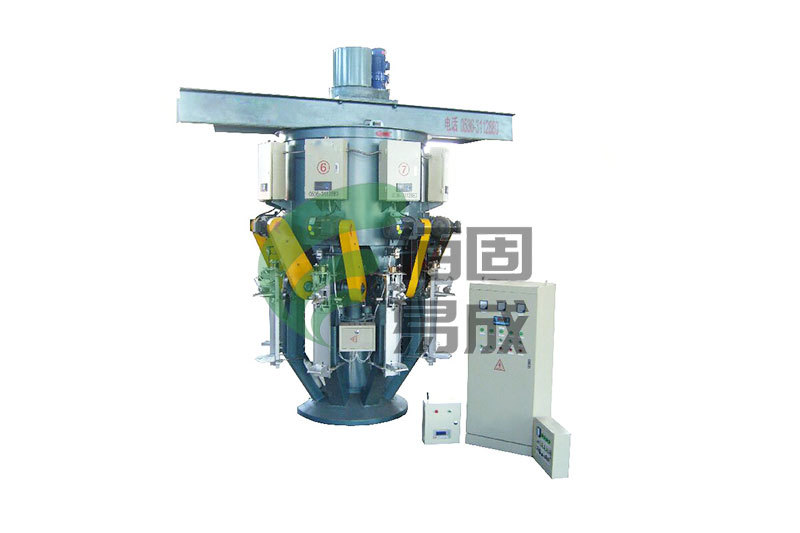

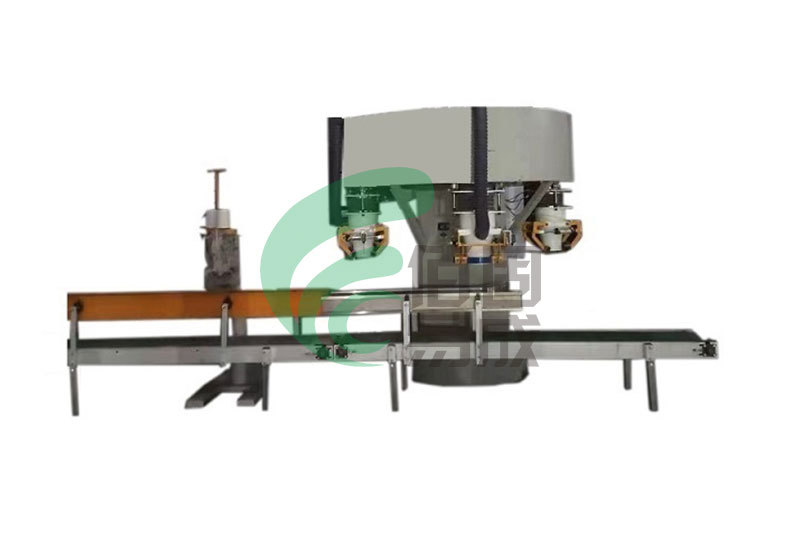

Ton Bag Packing Machine

This ton bag packing machine is a new generation intelligent packing product custom designed and manufactured by us according to the characteristics of packing materials and the demands of users. After manual bag hanging, the material filling, weighing and unhooking will all be done automatically. It is a multi-functional packing machine integrated with electronic weighing, automatic bag unloading, and automatic dusting. It has a high level of automation, stable performance and high precision of packing. Due to advanced technologies and few quick-wear parts, the machine provides great durability. Also, with programmable electronic control system, its control process is highly reliable. We’ve adopted advanced designs such as anti-dust and dusting openings to reduce dust pollution in the working environment.

Key words:

Category:

Details

| The name of the | unit | Technical parameters | The serial number | The name of the | unit | Technical parameters |

| Production capacity | b/h | 20-40 | 7 | The total power | kW | 7.4 |

| Weighing scale | t | 1~2 | 8 | Air pressure | Mpa | 0.5~0.8 |

| Measuring accuracy | ≤±0.5% | 9 | Gas consumption | m3/min | 0.06 | |

| Bag weight pass rate | ≥95% | 10 | Dust air volume | m3/h | 1500~3000 | |

| The feeding way | Two-speed feeding | 11 | The environment temperature | ℃ | - 10~40 | |

| The control mode | Instrument control | 12 | Installation dimensions | mm | 4500×2180×4200 |

Related Products

Online Message