Products

Product classification

Dry mortar automatic batching and packaging production line

Dry mortar production line is suitable for mixing, blending, metering and packaging of dry mortar, dry mixed mortar, thermal insulation mortar, ready-mixed mortar, additives, grouting agent, interfacial agent, putty powder, chemical powder and so on.

Learn more>

Concrete batching and mixing systems

Aggregate batching system adopts four-bin one-type modular structure, the aggregate bin body is conical structure, each hopper is equipped with two discharge gates at the bottom, and the opening of the gates is controlled by pneumatic cylinders.

Learn more>

Refractory dosing and packaging AA system

Refractory batching and packaging for new production lines and the retrofitting of old production lines and other processes applicable to the production of mobile batching.

Learn more>

Fertilizer special dosage packaging production line

The annual output of 100,000~300,000 tons of “economic and practical microcomputer batching (BB) fertilizer production line” researched and developed by our company is the key model promoted by the Ministry of Agriculture for soil testing and formula fertilizer application, which is in a leading position in China and is widely used in the continuous production of large and medium-sized BB fertilizers (blended fertilizers) enterprises.

Learn more>

Powder dosing and packaging integrated production line system

Our company developed the powder universal small-scale batching and packaging line can be widely used in chemical industry, building materials, food, refractory materials, feed, additives, micronized powder and other industries.

Learn more>

This system can be used in paint, ink, food, beverage, chemical, pharmaceutical and other industrial metering control automated production with a variety of liquid raw materials according to the formula for the proportion of weighing.

Learn more>

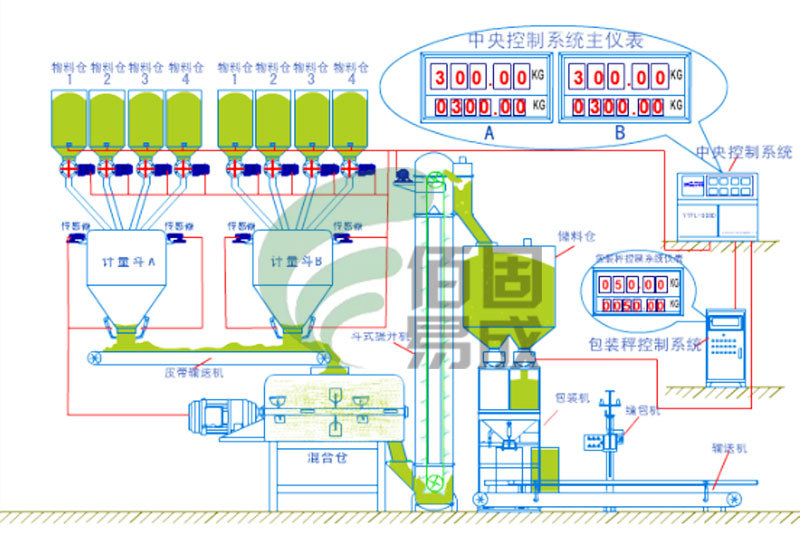

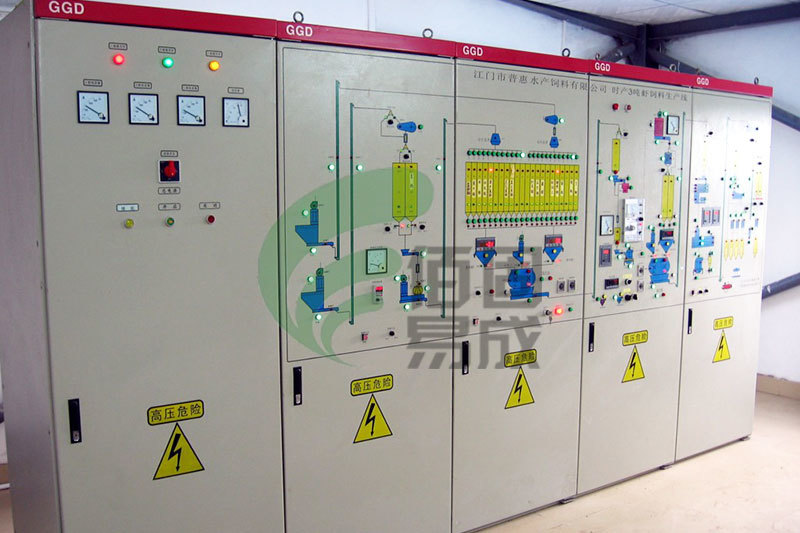

Automatic Feed Dosing and Packaging System

Function: Automatically complete the batching of 3-20 kinds of raw materials according to the specified weight proportion; batching capacity: 40 tons/hour.

Learn more>