Products

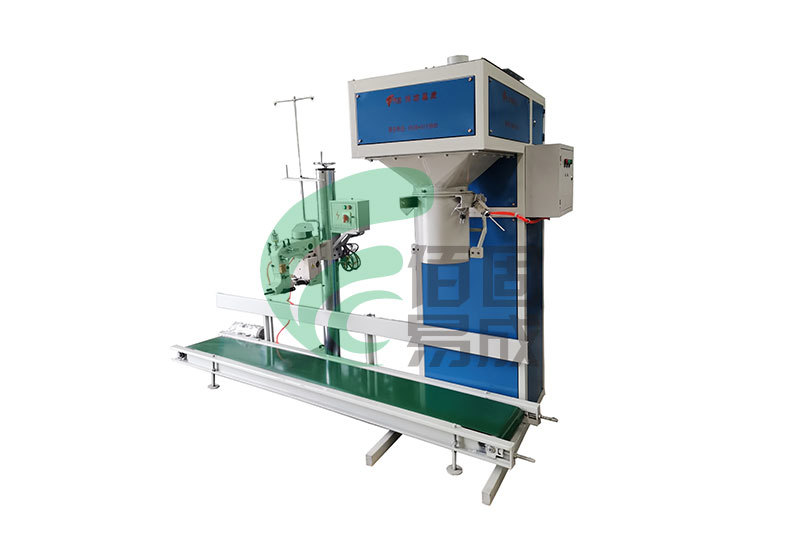

Granule Packaging Machine

Granule packaging machine can also be called open pocket packaging machine, is a new generation of intelligent packaging machine developed by our company, suitable for a variety of better fluidity of granular, powdery materials. Such as: fertilizers, chemicals, seeds, feed and other loose materials such as metering and packaging as well as sewing process after packaging. This machine is a fast quantitative packaging unit integrating filling, measuring, sealing, packaging and conveying. This machine is mainly used for 25-50kg quantitative packaging, there are two kinds of MDCS25 and MDCS50. The machine is characterized by reasonable structure, beautiful shape, smooth running, no need of packing power, energy saving and electricity saving, convenient operation and accurate weighing.

Category:

Key words:

Granule Packaging Machine

Whatsapp:

Email:

Details

| name (of a thing) | work unit (one's workplace) | Technical Parameters | |||

| Product Model | MDCS251 | MDCS252 | MDCS501 | MDCS502 | |

| production capacity | t/h | 8 | 12 | 10 | 15 |

| Weighing range | kg | 5~25 | 5~25 | 25~50 | 25~50 |

| Measurement accuracy | ±0.1%~0.5% | ||||

| Bag weight pass rate | ≥95% | ||||

| Belt power | kw | 0.37 | |||

| Belt width | mm | 350 | |||

| Sewing machine form | columnar | ||||

| pneumatic | Mpa | 0.4-0.8 | |||

| Equipment weight | Kg | 300 | 400 | 400 | 550 |

| Mounting Dimensions | mm | 3000*1100*2600 | 4800*1100*2600 | 3000*1100*2600 | 4800*1100*2600 |

Related Products

Online message

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you very much.