Products

HP Constant speed quantitative feeder

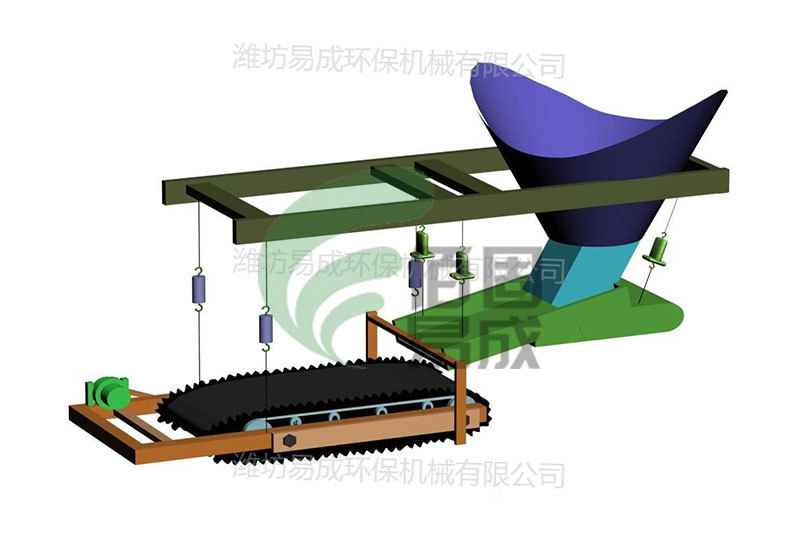

HP constant speed quantitative feeder (commonly known as constant speed belt feeder) is a new type of belt scale developed successfully by our company, which has the features of simple structure, small volume, easy installation, reasonable measurement mode, smooth operation, high measurement accuracy, etc. Compared with speed regulating scale and cantilever belt scale, the measurement accuracy is not affected by the belt jitter, belt thickness and roundness of the carrier stick, etc. The belt feeder has the features of simple structure, small volume, easy installation, reasonable measurement mode, smooth operation and high measurement accuracy.

Key words:

HP Constant speed quantitative feeder

Whatsapp:

Email:

Details

Product Overview

Product Overview Technical characteristics

Technical characteristics2. Unique hanging weighing method, high measuring precision, simple structure, excellent performance, reliable and stable operation.

3. The scale frame is made of cold-formed C-type steel plate, with novel structure and high strength, suitable for the design of various specifications of non-standard scales;

4. Ring-type jointless belt, can be selected according to the process: flat belt, baffle structure, skirt belt structure;

5. hanging belt scales by three high-precision tension sensors hanging vertically as a measuring mechanism, feeding can be used electric vibration machine, feeding belt machine or other conveying equipment.

Main technical parameters

Main technical parameters 1、Static measurement accuracy: 0.5%

2, dynamic measurement accuracy: ± 1% (equivalent accuracy)

3, measurement range: 0.2-30 tons / hour

4, the belt to adapt to the temperature: less than 50 ℃ (ordinary belt) or 80 ℃ (heat-resistant belt)

5、Using environment: -20℃~+50 ℃.

6、Control part It can be controlled by intelligent meter or industrial control machine system.

Selection table

Selection table|

Model parameters |

Belt width(mm) |

Distance between master and slave pulleys(mm) |

Maximum line speed(m/s) |

production capacity (m³/h) |

Motor power(kw) |

|

HP500a |

500 |

1000 |

0.143 |

19 |

0.75 |

|

HP650a |

650 |

1000 |

0.143 |

29 |

0.75 |

|

HP800a |

800 |

1200 |

0.134 |

40 |

1.1 |

|

HP1000a |

1000 |

1200 |

0.134 |

56 |

1.5 |

|

HP500b |

500 |

1000 |

0.29 |

40 |

0.75 |

|

HP650b |

650 |

1000 |

0.29 |

50 |

1.1 |

|

HP800b |

800 |

1200 |

0.293 |

80 |

1.1/1.5 |

|

HP1000b |

1000 |

1200 |

0.293 |

120 |

1.5 |

|

HP1200b |

1200 |

1500 |

0.36 |

160 |

2.2 |

|

HP1400b |

1400 |

1500 |

0.36 |

200 |

2.2/3.0 |

Working Principle

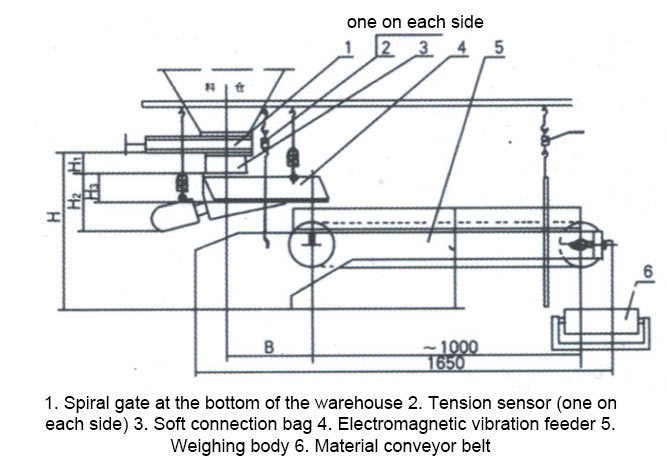

Working PrincipleHP belt type constant speed quantitative feeder when the measured weight in the silo reaches the lower limit position of the weighing hopper, the discharging screw machine or other actuators will fix the discharging amount according to the rotating speed at that time, and control the materials in the silo to go down to the weighing hopper quickly (manually or automatically), stop loading when the material is loaded to the upper limit of the weighing, the quick loading can shorten the time of feeding, and the system will restore the loss-in-weight measurement mode automatically, this mode can improve the accuracy of weighing more. The system automatically resumes the loss-in-weight weighing mode, which improves the weighing accuracy and control precision. In batch weighing loss-in-weight systems, the design is similar to that of continuous loss-in-weight systems, however, the accuracy of the final weight of the feeding (batch) cycle is higher than that of the actual feed volume control.

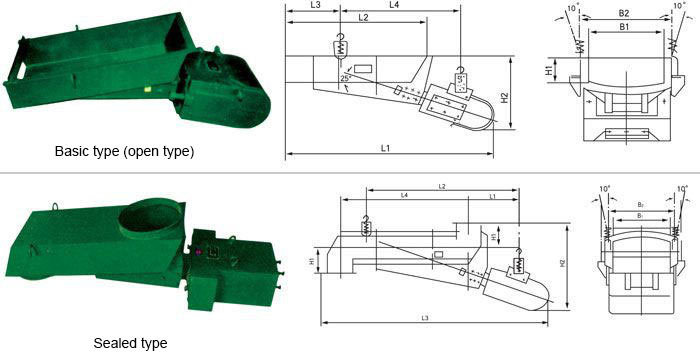

The electromagnetic vibrating feeder used in the HP Belt Constant Velocity Quantitative Feeder is a device that conveys materials under the action of a directional electromagnetic force. This equipment has harnessed power is small, there is no large starting current, does not cause network voltage drop, amplitude instantaneous can reach a stable value, you can immediately stop and run and so on, and also can be smooth stepless adjustment of the feeding volume, to achieve automatic control. However, the current domestic production of electromagnetic vibrating feeder, there are large size, voice, control part of the complexity of the price and other shortcomings.GZ series of electromagnetic vibrating feeder is used to block, granular and powdery materials, from the storage silo or hopper in a uniform and continuous or quantitative feeding to the receiving device, can be infinitely adjustable feeding volume, and to achieve the centralized control of the production process and automatic control. It is small in size, light in weight, easy to install, no rotating parts, no lubrication, easy to maintain, high working frequency, and consumes less electric energy. It is widely used in mining, metallurgy, coal, chemical industry, electric power, machinery, food and other industries. The maximum output of 1000T per hour is divided into sealed type and open type. On the basis of absorbing advanced technology at home and abroad, our company has recently designed a new type of GZ electromagnetic vibrating feeder, whose structure is shown in the figure.

structure plan

structure plan

Related Products

Online message

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you very much.