Products

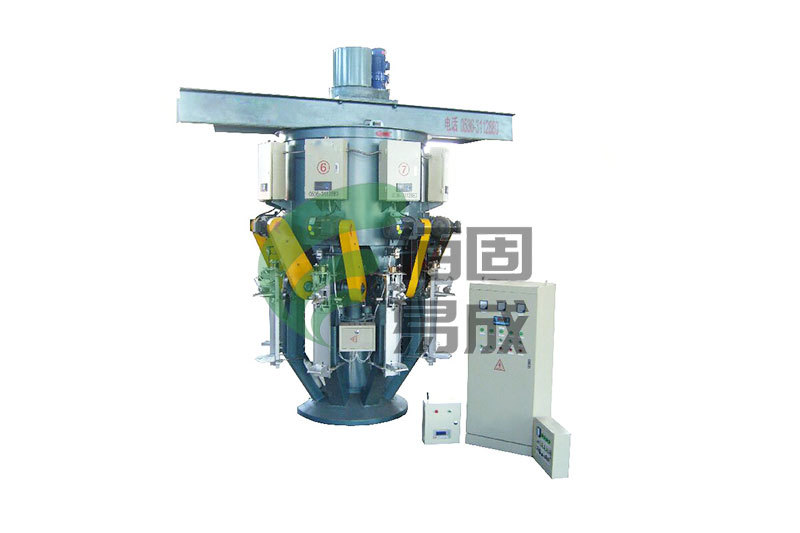

Rotary Cement Packaging Machine

MHB50-XA series digital cement packaging machine is our company at home and abroad on the basis of cement packaging machine automation control mechanism, dozens of development and improvement, independent research and development of advanced generation of automatic packaging equipment, the main control technology to reach the domestic level, the packaging machine increased online weight automatic correction and remote control function, to fill the domestic rotary packaging machine automation control of a blank, is the development of domestic revolutionary innovation in cement packaging machinery. MHB50-XA series digitalized cement packing machine is an excellent choice for the automatic packing of large and medium-sized cement enterprises.

Category:

Key words:

Rotary Cement Packaging Machine

Whatsapp:

Email:

Details

MHB50-XA Series CNC Cement Packaging Machine has the following features:

1. The weighing system is free of calibration, easy to operate, no need to mark the weighing and other cumbersome operations in the process of using.

2. The bag weight is automatically corrected during the packing process, which effectively ensures the qualified rate of bag weight.

3. Remote setting and synchronous modification of parameters, improving the effective working time of the operator.

4. No bag insertion without dust; accidental bag removal, broken bag automatically stop filling. Improves the working environment at the operation site.

5. Remote real-time view of the single nozzle filling process weight changes, monitoring the unloading bag weight.

6. The ash impeller is made of wear-resistant material and has a long service life.

7. The key control electrical parts adopt non-contact electronic devices, which can adapt to the harsh environment.

8. No mechanical gate actuator, solving the hidden danger of card gate.

9. Adopt advanced electromagnetic bag dropping device, which can guarantee trouble-free operation within one year.

10. The bag dropping action part adopts ball structure, and the service life is twenty times higher than that of conventional products.

11. The rotary main drive system is controlled by imported “ABB” frequency converter, which ensures the reliability of the system operation.

12. The remote controller is changed to liquid crystal display, which is more intuitive to display and more convenient to operate.

| Equipment Model | MHB50-4A | MHB50-6A | MHB50-8A | MHB50-10A | MHB50-12A |

| Number of discharge nozzles (pcs) | 4 | 6 | 8 | 10 | 12 |

| Bagging capacity (t/h) | 40-60 | 60—90 | 80—120 | 100—130 | 120--160 |

| Single bag weight (kg) | 49.8<M<50.6 | ||||

| Bag weight pass rate | >95% (20 bags total weight ≥1000 kg) | ||||

| Height of discharge nozzle from the ground (mm) | 1180 | ||||

| Discharge motor | Model: YE2-112M-4 Power: 4KW | ||||

| Supply Voltage | ~380V±10% | ||||

| direction of rotation | Clockwise (top view) | ||||

| Gas source pressure (MPa) | 0.5~0.8 | ||||

| Maximum rotating diameter (mm) | 1900 | 2200 | 2200 | 2400 | 2740 |

| Dust collection air volume (m³) | 13000 | 15000 | 22000 | 25000 | 25000 |

| Weight of the whole machine (t) | 4 | 5 | 6 | 7.5 | 9 |

Related Products

Online message

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you very much.