Products

Product classification

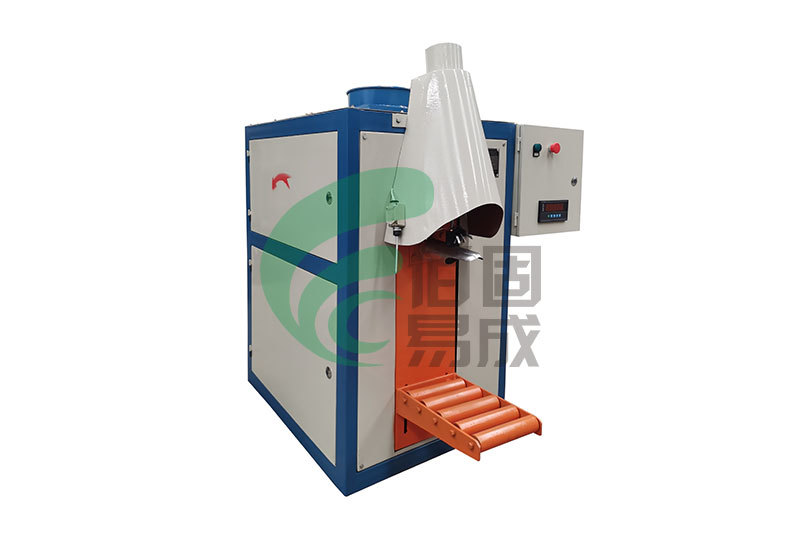

Fly ash packaging machine the entire working process of computer monitoring; instrumentation at any time to display; fault self-diagnosis; self-recovery; bag drop, broken bag automatic shutdown; also has an anti-clogging automatic shutdown function; a filling two measurement, precision has been greatly improved. The original electromagnet bag dropping and pneumatic door closing system improves the bag dropping function and ensures that the gray nozzle is not stuck and does not leak. The machine body is sealed to improve the working environment and reduce the labor intensity, which is well received by customers.

Learn more>

Putty powder packaging machine

The putty powder packaging machine is a new product developed by our factory to meet market demand, mainly divided into single nozzle packaging machine and double nozzle packaging machine. The characteristic of this machine is to change the traditional impeller feeding to spiral filling feeding, thereby solving the problem of high impeller feeding rate and unstable measurement of new national standard plastic woven packaging bags due to air resistance and insufficient filling. Spiral filling feeding can be sustained, smooth, fast, without air resistance, and has high productivity, so the new product was welcomed by a large number of building materials manufacturers as soon as it was launched.

Learn more>

Glass beads packaging machine is my company's scientific researchers for the density of small hollow particles of materials, especially developed a new generation of intelligent packaging machine for bleaching beads, hollow particles and other materials, but also for a variety of better mobility of granular (not more than 8mm), powder (not less than 38um) materials, such as: fertilizers, chemical industry, seeds, feed, and other loose materials such as metering and packaging process. The equipment is a set of bags, filling, measuring, packaging as one of the rapid quantitative packaging equipment, improve the working environment, reduce labor intensity, put into production since the majority of users welcome.

Learn more>

MZDQ100 mobile bagged cement truck loading machine is a new generation of conveying and loading equipment researched and developed by our company on the basis of introducing advanced technology from Germany. The equipment has high production efficiency, energy-saving and labor-saving, and its economic benefit is more than ten times of the manual bag loading, which is the preferred equipment for bagged cement loading in modern cement enterprises. MZDQ100 mobile bagged cement truck loading machine is the key equipment for bagged cement loading process in cement production enterprises. This equipment has a high degree of automation, and the whole loading process of unloading bags from the upper part of the car can be completed by one person. This product is also widely used in fertilizer, grain, feed and other industries for bagged packaging products, conveying and loading operations.

Learn more>

Single Nozzle Packaging Machine

MQB50 series of automatic impeller fixed single mouth packaging machine, is my company's own design and production of new packaging machine products, the company's technical personnel continue to research and development, has been in the country a number of building materials manufacturers to use, well received by the majority of users. The series of packaging machines throughout the working process of computer monitoring; instrumentation at any time to display; self-diagnostic fault; self-recovery; bag drop, broken bag automatic shutdown; also has an automatic shutdown function to prevent clogging; a filling two measurements, the accuracy of a greater improvement. The original electromagnet bag dropping and pneumatic door closing system improves the bag dropping function and ensures that the gray nozzle is not stuck and does not leak. The sealing of the machine body improves the working environment and reduces the labor intensity, which is highly praised by customers.

Learn more>

Double Nozzle Packaging Machine

MQB50 series automatic impeller fixed double mouth packaging machine, is my company's own design and production of new packaging machine products, the company's technical personnel continue to research and development, has been in the country a number of building materials manufacturers to use, well received by the majority of users. The series of packaging machines throughout the working process of computer monitoring; instrumentation at any time to display; self-diagnostic fault; self-recovery; bag drop, broken bag automatic shutdown; also has an automatic shutdown function to prevent clogging; a filling two measurements, the accuracy of a greater improvement. The original electromagnet bag dropping and pneumatic door closing system improves the bag dropping function and ensures that the gray nozzle is not stuck and does not leak. The sealing of the machine body improves the working environment and reduces the labor intensity, which is highly praised by customers.

Learn more>

MQB50 series of automatic impeller fixed three mouth packaging machine, is my company's own design and production of new packaging machine products, the company's technical personnel continue to research and development, has been in the country a number of building materials manufacturers to use, well received by the majority of users. The series of packaging machines throughout the working process of computer monitoring; instrumentation at any time to display; self-diagnostic fault; self-recovery; bag drop, broken bag automatic shutdown; also has an automatic shutdown function to prevent clogging; a filling two measurements, the accuracy of a greater improvement. The original electromagnet bag dropping and pneumatic closing system improve the bag dropping function and ensure that the gray mouth is not stuck and not leaking. The sealing of the machine body improves the working environment and reduces the labor intensity, which is highly praised by customers.

Learn more>

MQB50 series of automatic impeller fixed four mouth packaging machine, is my company's own design and production of new packaging machine products, the company's technical personnel continue to research and development, has been in the country a number of building materials manufacturers to use, well received by the majority of users. The series of packaging machines throughout the working process of computer monitoring; instrumentation at any time to display; self-diagnostic fault; self-recovery; bag drop, broken bag automatic shutdown; also has an automatic shutdown function to prevent clogging; a filling two measurements, the accuracy of a greater improvement. The original electromagnet bag dropping and pneumatic door closing system improves the bag dropping function and ensures that the gray nozzle is not stuck and does not leak. The sealing of the machine body improves the working environment and reduces the labor intensity, which is highly praised by customers.

Learn more>

MZDQ100 mobile loading machine is widely used in cement, chemical industry, chemical fertilizer, grain, feed and other industries for bagged packaging products conveying and loading due to its energy-saving, high loading efficiency, and has become the key equipment of the loading process. But in the mobile loading process also caused the unloading dust source point of movement and difficult to collect dust treatment, resulting in unloading dust secondary pollution. In order to solve this situation, our company developed a good dust removal effect dust removal efficiency of mobile loading dust removal system, through the actual installation and application of the majority of customers have been unanimously praised.

Learn more>

DZC rotor scale is composed of measuring scale body device, support device, speed measuring device, sensor measuring device and control system.

Learn more>

DEL/DEMSpeed regulating quantitative feeder

DEL/DEMSpeed regulating quantitative feeder, more applications in cement, mining, especially for mill batching feeding control DEL/DEM quantitative feeding belt scale-control process, for the continuous dynamic metering and quantitative feeding of bulk, lumpy, powdery materials.

Learn more>

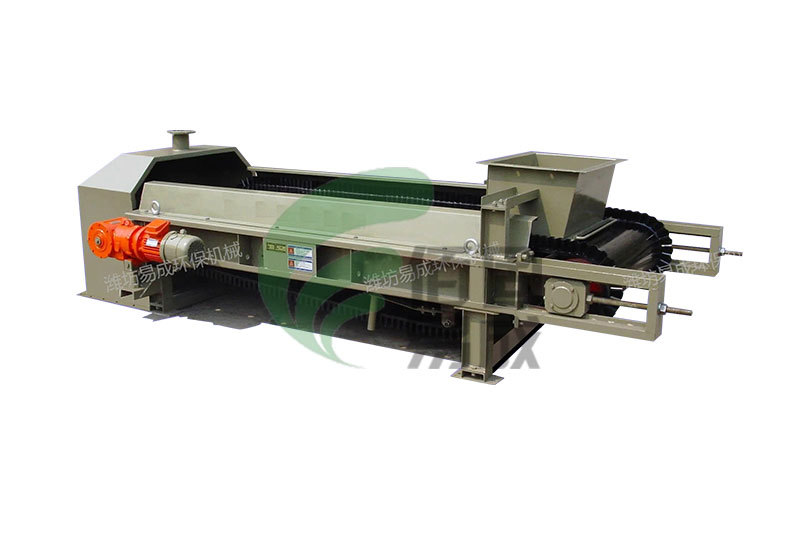

DJLarge Inclination Belt Conveyor

The structure of DJ type large inclination angle belt conveyor is to stick the freely retractable rubber waveform vertical “skirt” on both sides of the flat rubber transportation belt, and there is a certain strength and elasticity of the transverse partition board sticking between the skirts to form a box-shaped bucket, so that the materials can be continuously transported in the bucket.

Learn more>

HP Constant speed quantitative feeder

HP constant speed quantitative feeder (commonly known as constant speed belt feeder) is a new type of belt scale developed successfully by our company, which has the features of simple structure, small volume, easy installation, reasonable measurement mode, smooth operation, high measurement accuracy, etc. Compared with speed regulating scale and cantilever belt scale, the measurement accuracy is not affected by the belt jitter, belt thickness and roundness of the carrier stick, etc. The belt feeder has the features of simple structure, small volume, easy installation, reasonable measurement mode, smooth operation and high measurement accuracy.

Learn more>

LBQ-ILightweight chain conveyor

LBQ lightweight chain conveyor adopts low speed operation, the whole machine is stable, reliable and low failure rate.

Learn more>

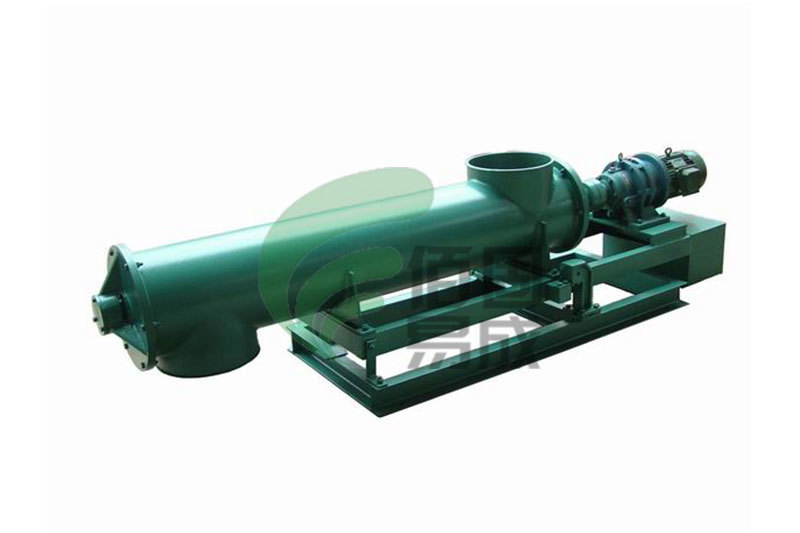

Screw quantitative feeder is commonly known as the winch said or spiral said, is a collection of powder conveying, weighing and measuring and quantitative feeding control as a whole, electromechanical automatic control integration products;

Learn more>

NE Series Plate Chain Bucket Elevator is suitable for conveying powdery, granular, small lumpy abrasive or non-abrasive materials, such as raw material, cement, coal, limestone, dry clay, clinker, etc., and the temperature of the materials is controlled to be below 250℃.

Learn more>